How to Properly Use Xstrap Wheel Strap with Swivel Hooks to Avoid Vehicle Damage

2026-02-03

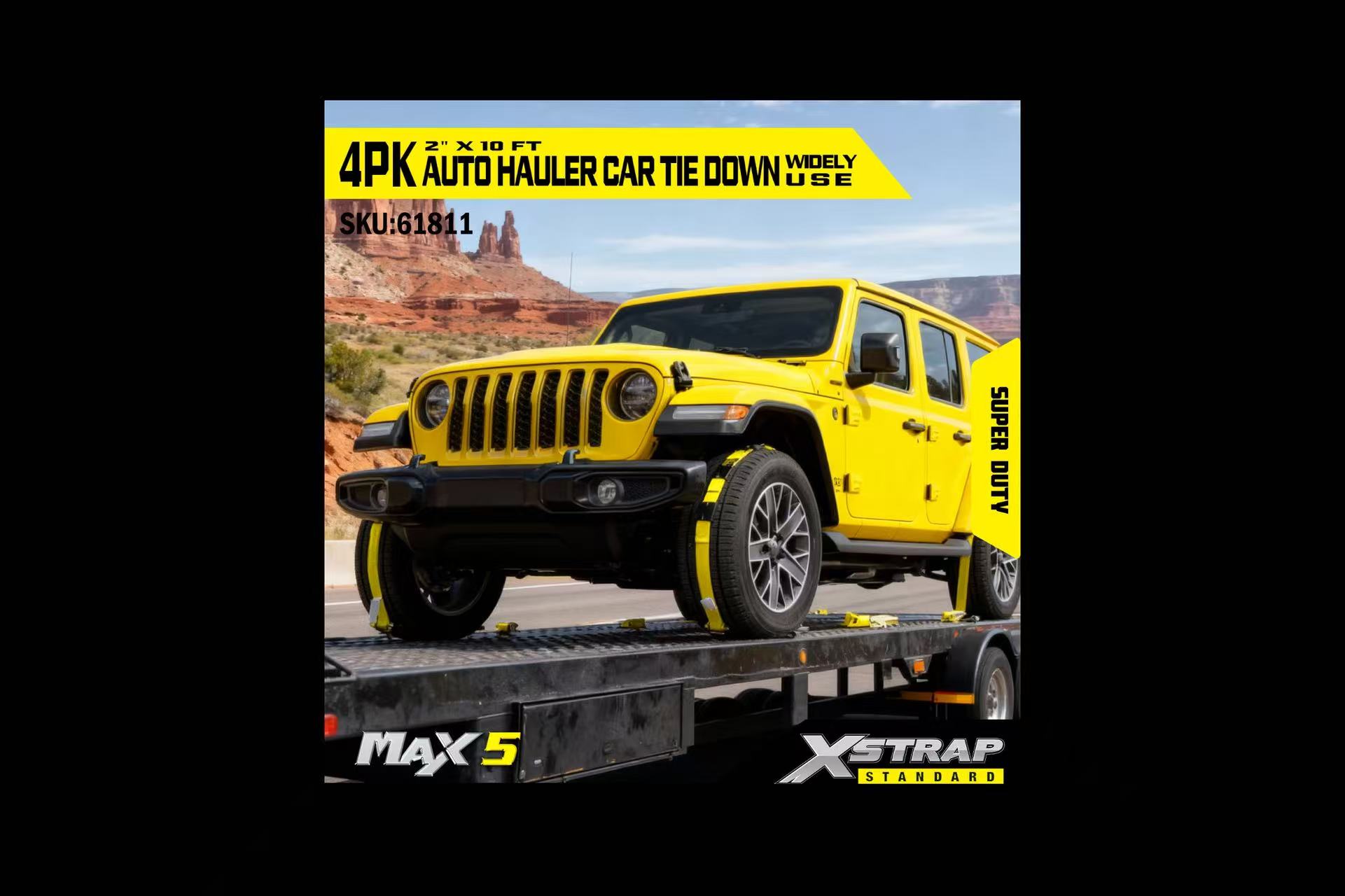

Transporting vehicles safely requires a restraint system designed specifically for vehicle hauling—not generic tie-downs. Using the wrong straps can restrict suspension movement, damage tires, or cause instability during transit.

Wheel straps with swivel hooks are engineered for this exact purpose. By securing the vehicle directly by the wheels and allowing controlled suspension travel, they provide a safer and more stable solution for car hauling. This guide focuses specifically on wheel straps with swivel hooks, explaining their key features, correct installation methods, and best practices to ensure secure, damage-free vehicle transport.

1. Why Proper Wheel Strap with Swivel Hooks Matter

Proper vehicle transport requires a restraint system that secures the vehicle without placing unnecessary stress on critical components. Unlike traditional frame-based tie-downs, wheel straps with swivel hooks are designed to secure the vehicle directly by the tires, allowing the suspension to function naturally during transit.

The swivel hooks provide flexible alignment with trailer anchor points, reducing twisting, uneven loading, and strap wear. Combined with wheel-based restraint, this design helps maintain consistent tension, minimizes movement caused by road vibration, and significantly lowers the risk of tire, suspension, or frame damage.

For both professional carriers and recreational haulers, wheel straps with swivel hooks offer a safer, more controlled, and vehicle-friendly solution—especially during long-distance transport or on uneven road conditions.

2. How to Choose the Wheel Strap with Swivel Hooks

Choosing the right wheel straps with swivel hooks is critical for safe and damage-free vehicle transport. Unlike general tie-down straps, wheel straps are designed to secure the vehicle by the tires, making correct specification, material, and hardware selection especially important.

When selecting wheel straps with swivel hooks, focus on the following key factors to ensure compatibility, strength, and long-term reliability.

- Load Capacity & Break Strength

Load capacity is one of the most important considerations when choosing wheel straps with swivel hooks. The straps must be strong enough to secure the vehicle under dynamic conditions such as braking, acceleration, and road vibration.

High-quality wheel straps with a 10,000 lbs break strength provide a critical safety margin, making them suitable for transporting cars, SUVs, pickup trucks, ATVs, and UTVs. Adequate break strength ensures the straps maintain consistent tension and stability throughout long-distance hauling.

- Webbing Material & Durability

Because wheel straps are in constant contact with tires, durability and abrasion resistance are essential. Premium wheel straps with swivel hooks are manufactured from industrial-grade polyester webbing, which offers excellent resistance to wear, moisture, and UV exposure.

This material maintains strength under repeated heavy-duty use and harsh outdoor conditions, reducing the risk of fraying, stretching, or premature failure during transport.

- Wheel Strap Design & Tire Protection

Proper wheel strap design directly affects both vehicle stability and tire protection. Integrated rubber blocks or wheel tie-down components help prevent the strap from slipping while protecting tire surfaces from abrasion or pressure damage.

Securing the vehicle by the wheels allows the suspension to move naturally during transit, minimizing stress on the frame, axles, and suspension components—an important advantage over frame-based tie-down methods.

- Swivel Hooks & Trailer Compatibility

Swivel hooks play a critical role in wheel strap performance. Designed to rotate freely, swivel hooks allow the strap to align naturally with trailer anchor points, reducing twisting, uneven loading, and localized wear on the webbing.

This flexibility improves overall strap longevity and ensures a more secure, stable connection to a wide range of trailer configurations.

3. How to Install Car Hauler Straps Correctly

This wheel strap system with swivel hooks includes 4 heavy-duty ratchet wheel straps, sliding rubber blocks, swivel J hooks, and a durable ratchet mechanism, all designed specifically for secure and vehicle-friendly transport.

Follow the step-by-step instructions below to correctly install wheel straps with swivel hooks and achieve stable, damage-free vehicle hauling.

Pre-Use Inspection (Recommended Before Every Transport)

Before installation, inspect each component to ensure proper function and safety. Check the wheel straps for signs of fraying or damage, confirm the sliding rubber blocks are intact, verify that the swivel J hooks’ safety latches close securely, and ensure the ratchet operates smoothly. Proper inspection helps maintain consistent tension and long-term performance.

Step 1: Position the Vehicle & Install Rubber Blocks

- Drive the vehicle slowly onto the trailer or flatbed, centering it to achieve even weight distribution. Engage the parking brake and shift the transmission into Park or gear.

- Position the included sliding rubber blocks around the tires. Adjust their placement by sliding them into position so they grip the tires securely. These rubber blocks are designed to prevent lateral movement while protecting tire surfaces from abrasion.

Step 2: Attach Swivel Hooks to Trailer Anchor Points

Take the wheel straps and attach the non-ratchet ends to the trailer’s anchor points using the swivel J hooks. Rotate the hooks as needed to align naturally with the anchor points, then close the safety latches to ensure a secure connection.

Step 3: Secure the Wheel Straps & Apply Tension

- Route the ratchet end of each wheel strap toward approved attachment points such as frame rails, axle housings, or factory tow hooks. Never attach straps to bumpers, plastic components, or non-load-bearing parts.

- Open the ratchet handle, feed the webbing through the slot, and pull by hand to remove excess slack.

- Pump the ratchet handle to tighten the strap until it is firm and the vehicle remains stable. Avoid over-tightening, as wheel straps are designed to secure the tires while allowing controlled suspension movement.

- Lock the ratchet handle flat and secure any excess webbing to prevent flapping during transit.

Step 4: Complete a 4-Point Wheel Strap Tie-Down (Critical for Safety)

Repeat Steps 2 and 3 for all four corners of the vehicle. This wheel strap system is designed for a 4-point tie-down configuration, which provides maximum stability and resistance to forward, backward, and lateral movement—especially during braking or on uneven road surfaces.

Step 5: Final Safety Check Before Transit

Gently push or pull the vehicle to confirm there is no movement. Double-check that all swivel hooks are properly latched and that the rubber blocks are securely gripping the tires. Remove wheel chocks (if used) only after all wheel straps are fully tensioned.

How to Release Wheel Straps with Swivel Hooks After Transport

- Lift the ratchet release lever and open the handle fully to disengage the gears and release tension.

- Open the swivel J hooks’ safety latches and detach them from the trailer or vehicle anchor points.

- Retract the webbing and store the wheel straps, rubber blocks, and hooks in a clean, dry location to extend service life.

4. Important Safety Tips When Using Wheel Straps with Swivel Hooks

- Do Not Over-Tighten or Leave Wheel Straps Loose

Wheel straps with swivel hooks are designed to secure the vehicle by the tires while allowing controlled suspension movement. Apply only enough tension to keep the vehicle stable on the trailer.

Over-tightening can place unnecessary stress on tires, suspension components, or wheel assemblies, while insufficient tension may allow the vehicle to shift during braking or road vibration. During transport, periodically check the wheel straps to ensure tension remains consistent.

- Inspect Wheel Straps and Hardware Regularly

Because wheel straps are load-bearing components, regular inspection is essential for safe operation. Before each use, check the wheel straps for signs of fraying, cuts, or weakened stitching.

Pay close attention to the swivel hooks and ratchet mechanisms. Ensure safety latches close properly, hooks rotate freely, and ratchets are rust-free and fully functional. Any damaged or worn component should be replaced immediately to prevent failure during transport.

- Monitor Wheel Straps During Transport

Proper use of wheel straps with swivel hooks requires ongoing monitoring throughout the journey.\n\n- Check Tension: Recheck strap tension after the first few miles and periodically during long-distance hauling, as road vibration may cause slight loosening.\n- Watch for Movement: Visually inspect the vehicle to confirm it remains properly aligned and that the wheel straps stay positioned correctly on the tires.

Conclusion

Using wheel straps with swivel hooks correctly is essential for safe, stable, and vehicle-friendly transport. By selecting wheel straps with adequate break strength, installing them correctly, and following proper tensioning and inspection practices, users can significantly reduce the risk of shifting, damage, or strap failure. The swivel hook design further enhances stability by allowing natural alignment with trailer anchor points and maintaining consistent load distribution. Whether for professional vehicle hauling or recreational transport, wheel straps with swivel hooks provide a reliable and purpose-built solution for securing vehicles with confidence—especially during long-distance or demanding transport conditions.