Since its establishment in 2002,

Zhangjiagang SMK MFG. Co., Ltd. has specialized in cargo securing and control products, with over 20 years of experience in R&D and global export. The company is China Tie Down Hardware Manufacturers and Wholesale Tie Down Hardware Factory, and operates three factories and a large-scale warehouse center, forming an efficient international supply network.

SMK's product range includes tie-down straps, bungee cords, tow straps, lifting slings, hoists, and 4x4 accessories, widely used in transportation, logistics, outdoor, and industrial sectors. Its in-house brand XSTRAP enjoys strong recognition in global markets, alongside flexible OEM/ODM services for customized needs.

With over 8,000 sqm of production space, SMK is equipped with advanced automated lines and in-house testing labs, ensuring full-process quality control from raw material to finished goods. The company is ISO 9001 certified, SMETA audited, and has passed C-TPAT anti-terrorism inspections and multiple GS and patent certifications.

Looking ahead, SMK will continue to upgrade its cargo control systems, stay close to customer needs, and provide high-quality, efficient products and services worldwide.

Products

-

New Products

- Flatbed Solutions

- Interior Van Solutions

- Utility Tie down and Bungee Cord

- Auto Transport and Towing Solutions

- Lifting Solutions

- Tie Down Hardware

-

TUV&GS Certificated Tie Down and Bungee Cord

-

Towing & Rigging

-

4×4 Off-Road & Trailers

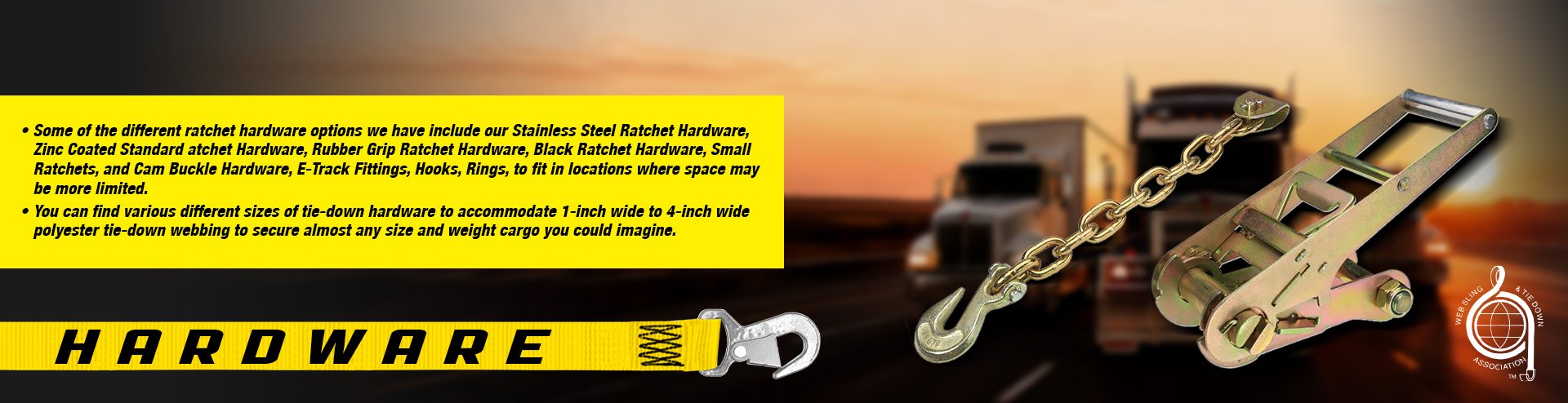

Wholesale and manufacture of ratchet straps hardware

Xstrap also provides ratchet buckles, cam buckles, s hooks, wire hooks, flat hooks and other related hardware. We can provide you with a one-stop solution.

-

In the world of logistics and transport, cargo securement is not just a matter of convenience; it is a critical safety requirement. A ratchet tie down is a high-strength ...

LEARN MORE -

Zhangjiagang SMK MFG. Co., Ltd. is a company with over 20 years of experience in tie down straps. We specialize in producing cargo securing products including Ratchet Str...

LEARN MORE -

The Core Role of Car Tie Down Straps in Vehicle Transport Safety Compliance and Legal Standards In the world of road transport, the use of Car Tie Down Straps is strictly...

LEARN MORE -

Deep Dive into the Core Role of Ratchet Tie Down In modern logistics, industrial transportation, and daily household moving, the Ratchet Tie Down is the most critical too...

LEARN MORE -

I. Fundamental Security: Ensuring Cargo Transportation Safety 1.1. Basic Principles of Loading Safety: Why Proper Securing is Crucial? Cargo is not static during transpor...

LEARN MORE -

Understanding the Role of Industrial Tie Downs in Secure Transportation Defining Industrial Tie Downs and Their Purpose Industrial Tie Downs, also known as cargo secureme...

LEARN MORE -

Xstrap participated in the VIETNAM EXPO HCMC 2025 as a visitor these two days. The expo covers four major exhibition zones showcasing advanced products and technologie...

LEARN MORE -

An In-Depth Look at Ratchet Straps vs. Lashing Straps In the realm of freight shipping and containment, selecting the correct tie-down straps is paramount for ensuring tr...

LEARN MORE

How the Structure Design of Tie Down Hardware Affects the Load Capacity of Tie Down Straps

In modern transportation, logistics, and industrial operations, tie-down straps and their related hardware are critical components for securing cargo safely. The hardware not only bears the tension of the straps but also directly affects the reliability and stability of the entire cargo securing system. Zhangjiagang SMK MFG. Co., Ltd., a manufacturer specializing in cargo control products, leverages over 20 years of experience to provide high-quality XSTRAP series tie-down straps and accessories for clients worldwide.

The Impact of Metal Hooks and Buckles on Load Capacity

Tie-down straps are typically connected to cargo or vehicle anchor points through metal hooks, buckles, or ratchets. The design of these components directly determines load transfer efficiency and safety margin. For example, the thickness, curvature radius, and load-bearing slot of hooks affect stress concentration points. Zhangjiagang SMK MFG. Co., Ltd.'s XSTRAP hooks use high-strength carbon steel and stainless steel materials and optimized welds to minimize local stress concentration, ensuring reliability under extreme loads.

Buckle and Ratchet Design Optimization

Buckles and ratchets are also critical. Traditional buckles may lose overall tension due to uneven friction or material deformation. XSTRAP ratchets employ multi-ratio gears and reinforced metal pawls to evenly distribute strap tension, increasing load capacity and reducing wear, which extends service life.

Material Selection and Structural Load Optimization

The choice of material and structural design are closely related. High-strength steel, aluminum alloys, and heat-treated metals each provide different load-bearing advantages, while structural design determines how well the material's properties are utilized. XSTRAP hardware features thickened stress points, additional support ribs, and optimized hook openings to achieve high strength and durability. This ensures straps remain stable under heavy loads, safeguarding cargo during transport.

Coordinated Design Between Hardware and Straps

Hardware structure not only affects its own load capacity but also the uniformity of strap tension. The angle, radius, and friction coefficient at the contact points determine how force is transmitted. Zhangjiagang SMK MFG. Co., Ltd. conducts laboratory simulations to optimize hardware design, ensuring straps are evenly loaded and reducing localized wear or breakage. OEM/ODM customization is available to meet specific client requirements.

Structural Reliability in Extreme Environments

In transportation and industrial applications, tie down hardware is often exposed to high and low temperatures, moisture, or salt spray. A rational structural design can reduce the environmental impact on load capacity. XSTRAP hardware uses zinc plating, anti-corrosion coatings, and high-wear alloys combined with enclosed designs to protect against corrosion and maintain stable performance under extreme conditions.

Full-Process Quality Control Ensuring Structural Stability

Zhangjiagang SMK MFG. Co., Ltd. operates over 8,000 sqm of production space across three factories, equipped with automated production lines and in-house testing labs. From raw material procurement to finished product inspection, each step is tightly controlled. ISO 9001 certification and SMETA audits ensure consistent hardware structure and that tie-down systems meet expected load requirements.

Design Standards and Load Limits of Tie Down Hardware

In modern logistics, industrial lifting, and outdoor transport, tie-down hardware is central to the safety of tie-down strap systems. Design standards and load limits directly impact cargo securing performance. Zhangjiagang SMK MFG. Co., Ltd., leveraging extensive R&D and testing capabilities, provides high-reliability XSTRAP products to ensure safe global transport.

The Importance of Design Standards

Design standards ensure hardware can reliably bear loads. Different applications require different strength, durability, and safety factors. XSTRAP products adhere to international standards such as EN 12195 and DIN 5688, using scientific design specifications to unify strength, durability, and safety.

Design Standards Include:

- Material selection

- Structural shapes

- Connector dimensions

- Weld quality

- Surface treatment

During development, Zhangjiagang SMK MFG. Co., Ltd. uses finite element analysis to simulate stress distribution under varying loads, optimizing hooks, buckles, ratchets, and slings to maximize load capacity and prevent failure due to stress concentration.

Methods for Determining Load Limits

The working load limit (WLL) is the maximum static load the hardware can safely carry, usually 1/3 to 1/5 of breaking strength for safety margin. XSTRAP hardware undergoes strict laboratory and quality control testing to determine load limits.

Material Mechanical Testing

High-strength carbon steel, stainless steel, and aluminum alloy materials are tested for tensile, compression, and impact performance to determine yield strength, ultimate strength, and fatigue resistance.

Hardware Component Load Testing

Simulated strap systems are tested under static and cyclic loads to evaluate deformation and wear.

Safety Factor Verification

Safety factors of 3–5x are applied according to application. Experimental data and finite element analysis ensure hardware maintains sufficient margin at maximum load.

Environmental Adaptability Testing

Hardware is tested in high/low temperatures, salt spray, and humidity to ensure load capacity remains stable.

Hardware Design and Strap System Performance

Hardware load limits directly influence the overall system. Optimizing hook curvature, buckle gear ratios, and ratchet pawl structures ensures straps and hardware work in coordination for maximum load-bearing performance. Customized designs are available to meet specific cargo and transport needs.

Full-Process Quality Control

With over 8,000 sqm of production space, advanced automated lines, and in-house testing labs, Zhangjiagang SMK MFG. Co., Ltd. ensures consistent hardware performance through each production step. ISO 9001, SMETA audits, and multiple GS certifications guarantee reliable and safe hardware.

How to Properly Install Ratchets and Buckles to Ensure Safety and Stability

The safety of tie-down strap systems depends not only on high-quality straps and hardware but also on correct installation and use of ratchets and buckles. Incorrect installation can reduce load capacity or cause cargo movement. Zhangjiagang SMK MFG. Co., Ltd. provides user-friendly, reliable XSTRAP products designed for proper operation.

Key Steps for Ratchet Installation

Choosing the Correct Anchor Point

Install ratchets parallel to and firmly anchored at the cargo point. XSTRAP ratchets feature reinforced base plates and optimized rotation mechanisms for stability under vibration or complex environments.

Threading the Strap Through the Ratchet

Ensure the strap is flat and untwisted. XSTRAP high-friction polyester webbing is precisely matched to the ratchet gear for maximum efficiency and safety.

Even Tensioning and Locking

Tension in stages, avoid over-tightening at once. Multi-ratio gear design allows controlled tensioning, ensuring cargo stability during transport.

Buckle Installation Precautions

Buckle and Strap Compatibility

Confirm buckle width matches the strap. XSTRAP buckles come in multiple sizes to prevent slipping or loosening.

Threading the Strap

Follow the manufacturer's threading method to create a stable friction surface. Internal tooth design maximizes grip under load.

Adjusting and Locking

After adjusting strap length, ensure the buckle is fully locked and check for any slip by lightly pulling. Reinforced pawls and plates ensure secure locking.

Importance of Coordinated Installation

Ratchets and buckles work together. Testing ensures optimized size ratios, friction fit, and load direction, maximizing system performance, strap durability, and service life.

Environmental and Safety Considerations

Ratchets and buckles may be exposed to extreme temperatures, humidity, and salt spray. XSTRAP hardware uses zinc-plating, stainless steel, and anti-wear coatings to maintain stability and performance under these conditions.

Full-Process Quality Assurance

Zhangjiagang SMK MFG. Co., Ltd. operates 8,000 sqm of production space with three factories and automated lines. Every step from material procurement to finished product testing ensures high reliability and safety of XSTRAP hardware.

Common Failure Modes of Tie Down Hardware in Use

Tie down hardware is essential for secure transport and industrial applications. Due to varying loads, environments, and handling, hardware may experience different failure modes. Zhangjiagang SMK MFG. Co., Ltd., with over 20 years of experience, provides high-reliability XSTRAP hardware, minimizing failure risks.

Overload Failure

Overload occurs when hardware is subjected to forces beyond its design capacity, potentially causing bending, breakage, or pawl slippage. Causes include inaccurate cargo weight estimation or uneven tensioning. XSTRAP hardware uses high-strength materials and optimized structure to remain stable under high loads.

Fatigue Failure

Repeated use may cause fatigue failure, where micro-cracks expand over time and lead to breakage. Vibrations, friction, and impact during transport contribute. XSTRAP hardware uses finite element analysis and life testing to optimize design, with high-toughness steel and wear-resistant coatings improving durability under cyclic loads.

Wear and Friction Failure

Long-term friction between strap and hardware can wear hooks, teeth, or ratchets, reducing locking stability or causing slippage. High-precision gears and wear-resistant metals in XSTRAP maintain even friction and extend service life.

Corrosion and Environmental Failure

Outdoor, marine, and humid conditions can cause corrosion, reducing load capacity. XSTRAP uses zinc plating, anti-corrosion coatings, and stainless steel, with environmental adaptability tests to ensure consistent performance.

Improper Operation

Incorrect installation or use, such as unsecured ratchets, twisted straps, or unlocked buckles, can cause failure. XSTRAP hardware is designed for smooth operation and comes with detailed guidelines to reduce human error risks.

Fatigue Cracks and Weld Failure

Welds or connections may develop micro-cracks under repeated stress, leading to breakage. Reinforced welding and precision inspection ensure long-term safety and reliability.