Since its establishment in 2002,

Zhangjiagang SMK MFG. Co., Ltd.

has specialized in cargo securing and control products, with over 20 years of experience in R&D and global export. The company is China 2 Inch Ratchet Straps Manufacturers and Custom 2 Inch Ratchet Straps Suppliers, and operates three factories and a large-scale warehouse center, forming an efficient international supply network.

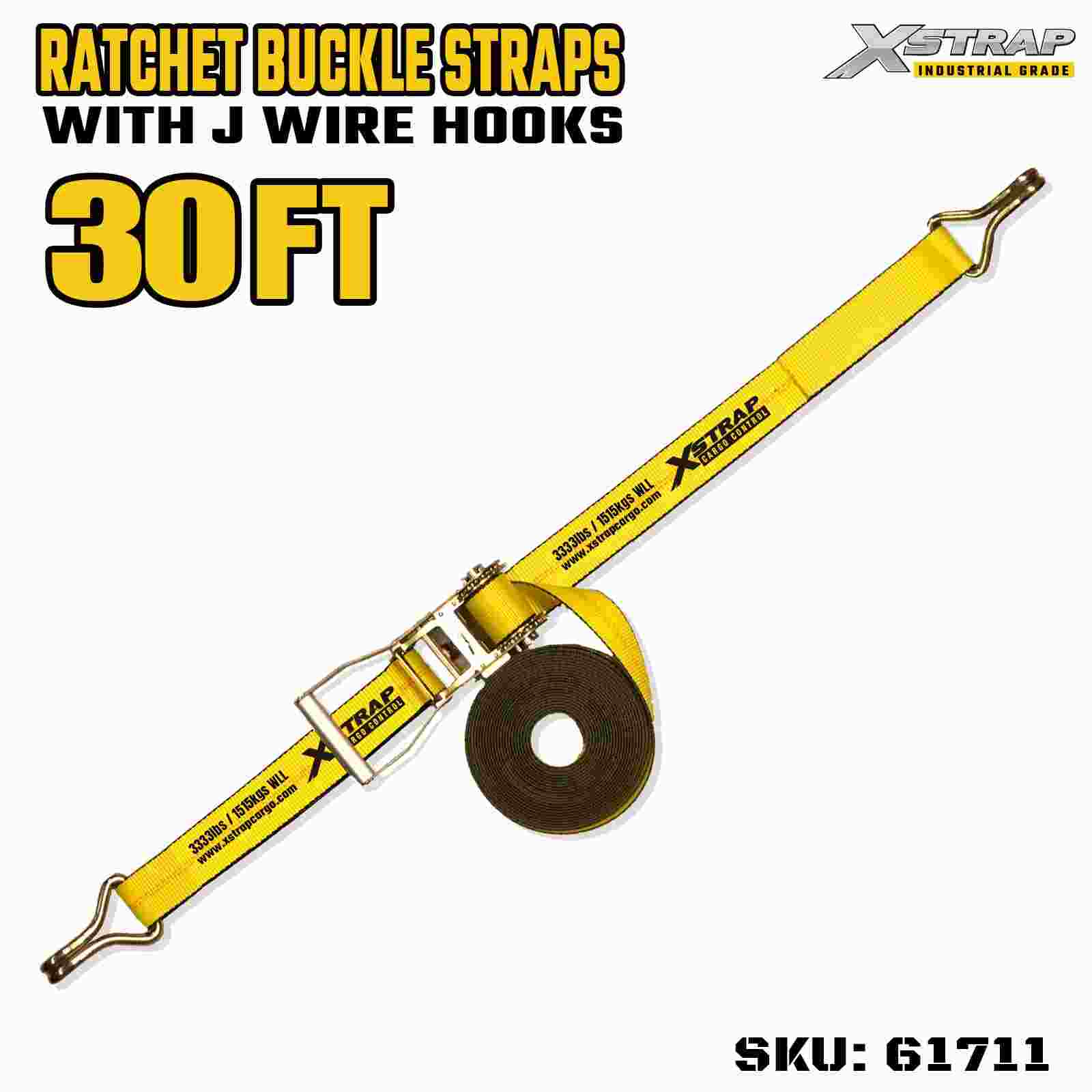

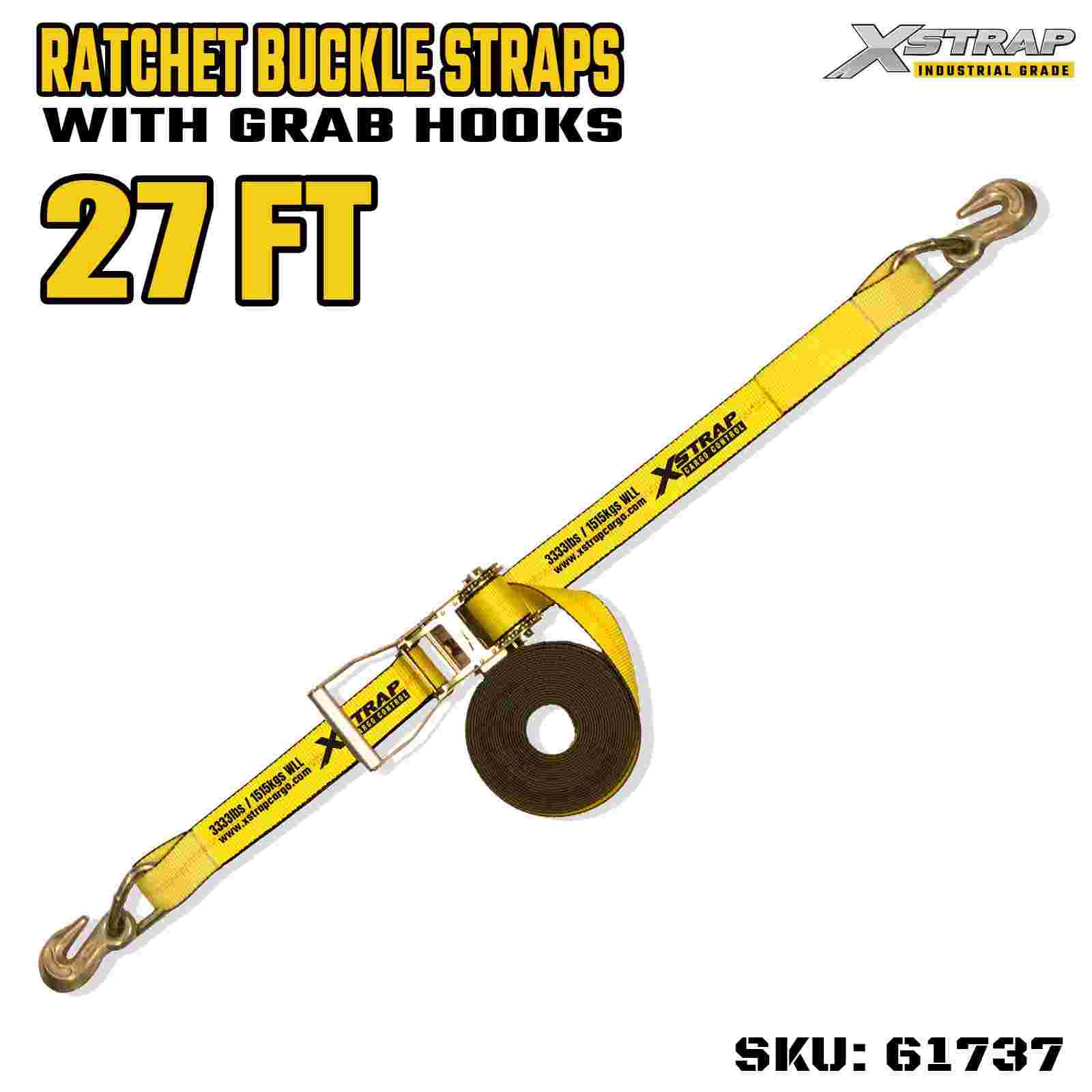

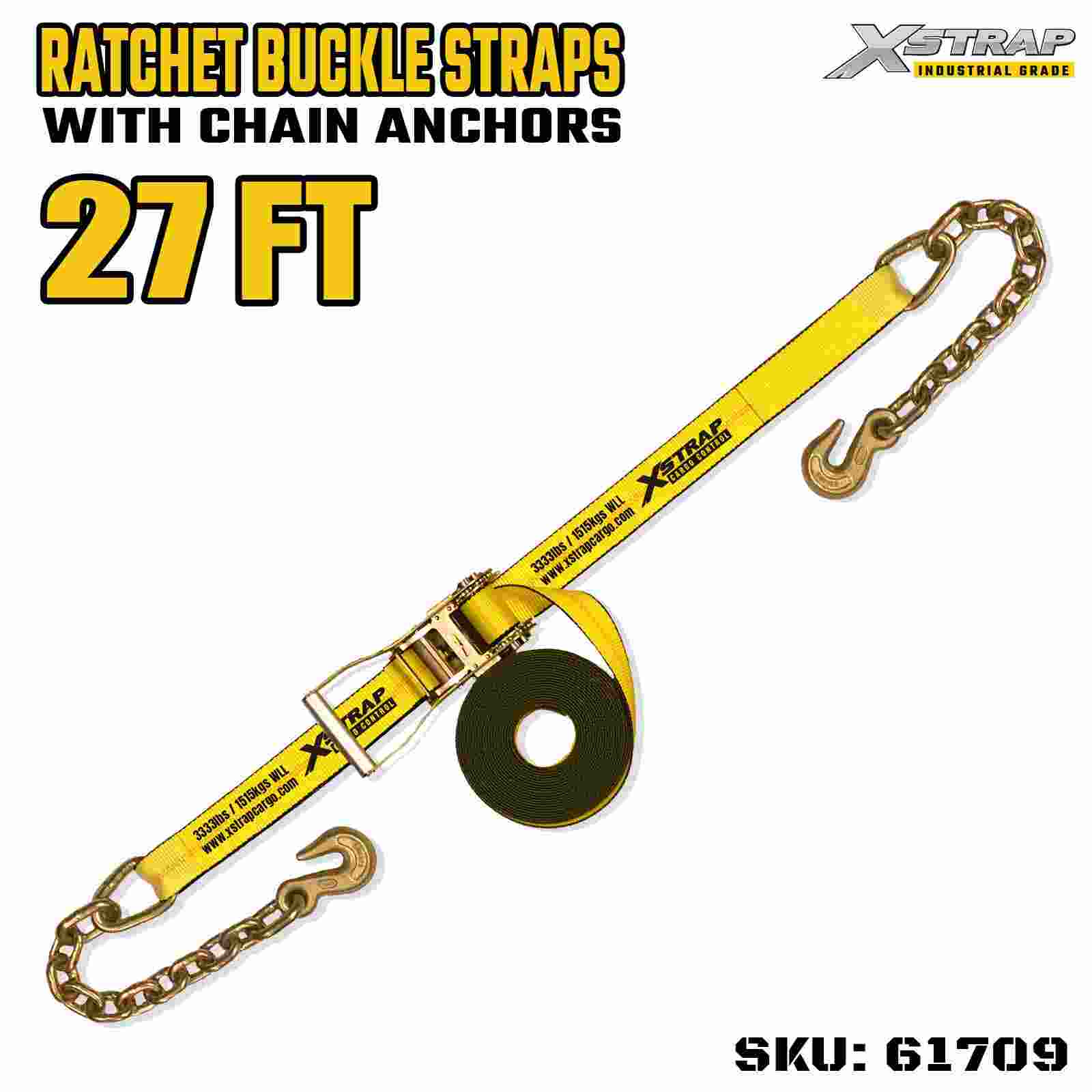

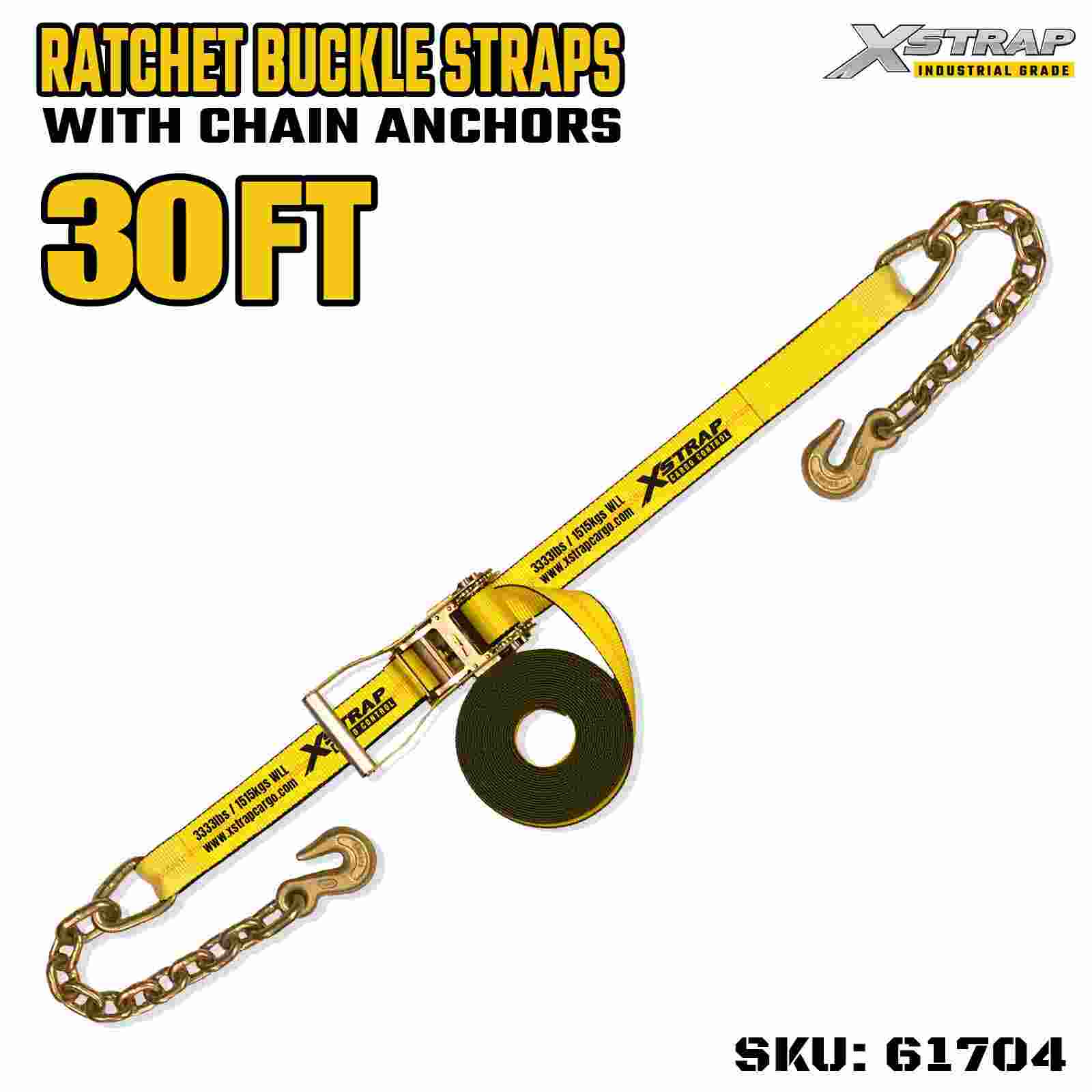

SMK's product range includes tie-down straps, bungee cords, tow straps, lifting slings, hoists, and 4x4 accessories, widely used in transportation, logistics, outdoor, and industrial sectors. Its in-house brand XSTRAP enjoys strong recognition in global markets, alongside flexible OEM/ODM services for customized needs.

With over 8,000 sqm of production space, SMK is equipped with advanced automated lines and in-house testing labs, ensuring full-process quality control from raw material to finished goods. The company is ISO 9001 certified, SMETA audited, and has passed C-TPAT anti-terrorism inspections and multiple GS and patent certifications.

Looking ahead, SMK will continue to upgrade its cargo control systems, stay close to customer needs, and provide high-quality, efficient products and services worldwide.

Product

-

New Products

- Flatbed Solutions

- Interior Van Solutions

- Utility Tie down and Bungee Cord

- Auto Transport and Towing Solutions

- Lifting Solutions

- Tie Down Hardware

-

TUV&GS Certificated Tie Down and Bungee Cord

-

Towing & Rigging

-

4×4 Off-Road & Trailers

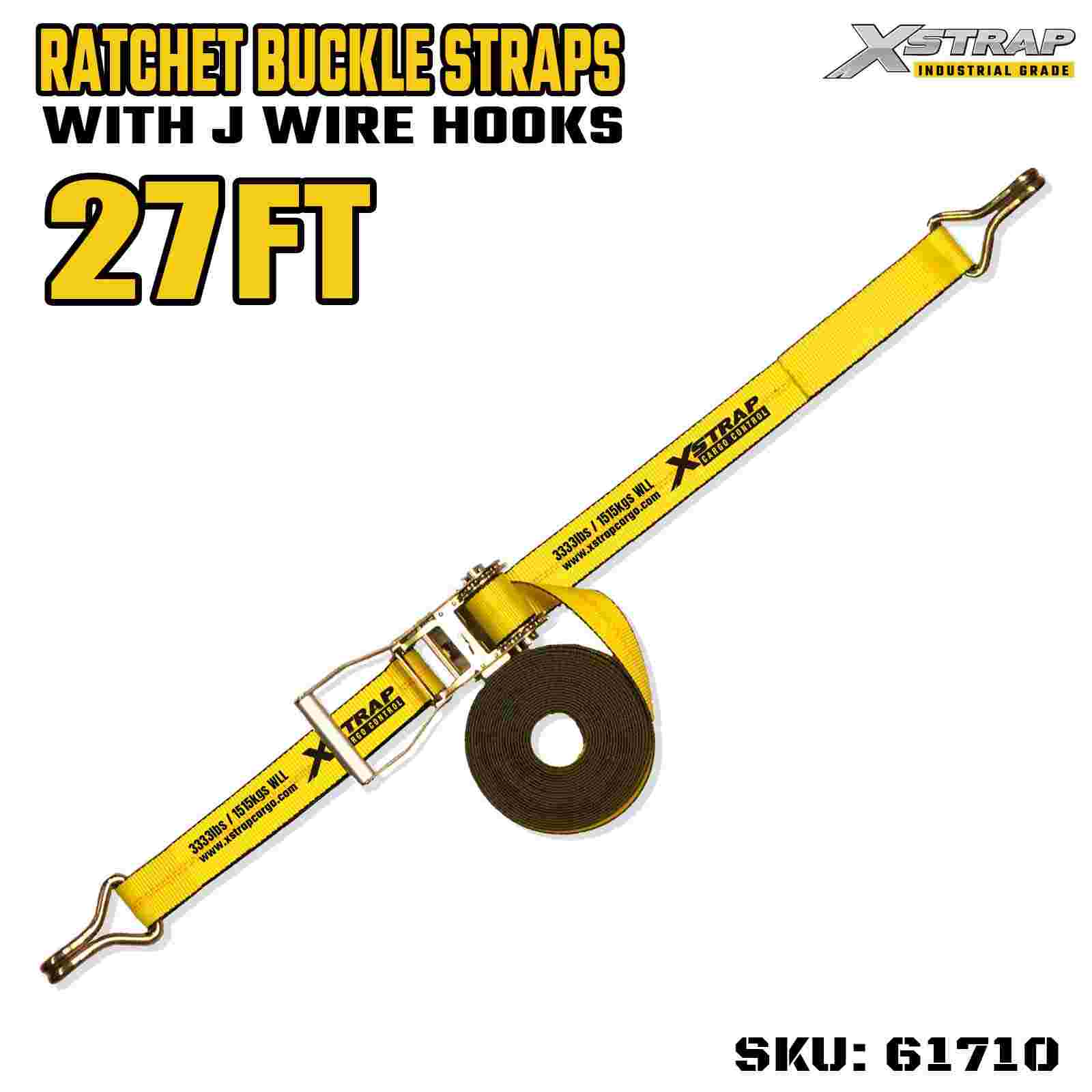

Wholesale and manufactures of 2 Inch Ratchet Straps industrial grade

-

Understanding the Role of Tow Dolly Basket Straps in Vehicle Transport In the field of vehicle transport, Tow Dolly Basket Straps are recognized as one of the safest and most stable securing tools ava...

READ MORE -

1. Understanding the Role of Chain Binders in Load Securement In the world of heavy transportation, Chain Binders are essential tools for ensuring cargo stability. They utilize either a lever principl...

READ MORE -

Understanding the Role of Car Tie Down Straps in Vehicle Transport Safety is the primary consideration when transporting a vehicle. Although standard cargo straps may look similar to Car Tie Down Stra...

READ MORE -

In the field of cargo transportation, securing loads is crucial to ensure the safety of both the cargo and the vehicle. Over the years, ratchet straps have been widely used to secure loads. However, w...

READ MORE

How Does the Webbing Material Choice (e.g., Polyester) for 2-Inch Ratchet Straps Affect Elongation, Weather Resistance, and Abrasion Resistance?

In the field of heavy-duty transport and cargo securing, the 2-inch ratchet tie-down strap is a crucial tool for ensuring cargo safety. However, the reliability of a strap is not solely determined by the mechanical strength of the ratchet; the choice of webbing material is the foundation that dictates the product's long-term performance, safety, and economic efficiency.

As a manufacturer specializing in cargo securing products R&D and global export since its establishment in 2002, Zhangjiagang SMK MFG. Co., Ltd. (SMK) understands the critical importance of material science. With over 20 years of expertise, the core of all our 2-inch tie-down straps—the webbing—primarily utilizes high-performance Polyester fiber. Below, we will detail how this choice fundamentally impacts the strap’s Elongation, Weather Resistance, and Abrasion Resistance, thus demonstrating the superior value of SMK products.

I. Impact of Webbing Material on Elongation: The Core of Safety and Stability

Elongation refers to the degree to which the webbing stretches under load. In cargo securing, low elongation is a vital safety characteristic.

- Advantages of Polyester Fiber: Polyester fiber exhibits extremely low elongation under its Working Load Limit (WLL) compared to Nylon or other natural fibers, typically well below industry standards. This is essential for stability during transit.

- Ensuring Tension Durability: When cargo attempts to shift during transport due to vibration or impact, low-elongation webbing quickly resists deformation, maintaining the set Pre-Tension and Standard Tension Force (STF), effectively preventing cargo from loosening or shifting.

- SMK's Quality Control: With over two decades of R&D experience, Zhangjiagang SMK MFG. Co., Ltd. (SMK) finely tunes the weaving density and heat-setting process of the webbing. Our products ensure elongation is minimized, providing customers with a "tight and secure" fastening effect, which is why our in-house brand XSTRAP enjoys strong recognition in global markets.

II. Impact of Webbing Material on Weather Resistance: Meeting Global Environmental Challenges

Cargo transport often involves complex outdoor environments, and the weather resistance of the webbing directly affects its service life and safety.

- Resistance to UV Degradation: Polyester fiber is inherently resistant to UV radiation. SMK further enhances the webbing's anti-aging performance by adding high-performance UV stabilizers during the raw material stage and utilizing our advanced automated production lines. This ensures that the webbing's structural integrity and color (for customized colors) remain stable even during prolonged exposure to strong sunlight, reducing premature failure due to UV degradation.

- Moisture and Chemical Resistance: Polyester features excellent hydrophobic properties, meaning it does not absorb significant moisture and suffer strength loss or mildew in damp environments, unlike nylon. It also exhibits good resistance to most common chemicals, oils, and acidic substances. This allows SMK's 2-inch tie-down straps to maintain high performance in cross-ocean shipping or harsh industrial settings.

- Compliance with International Standards: SMK is not only ISO 9001 certified but also operates in-house testing labs to rigorously test webbing performance under various climatic conditions, ensuring full compliance with international standards and customer expectations.

III. Impact of Webbing Material on Abrasion Resistance: Key to Extended Lifespan

Abrasion is a primary cause of strap failure. Improving abrasion resistance significantly extends the product's lifespan and reduces operational costs for the customer.

- High-Strength Weave Structure: The polyester fiber selected by SMK possesses high strength and tenacity. By precisely controlling the weaving density and pattern of the webbing, our 2-inch straps have a tighter, smoother surface that effectively resists friction and cutting forces generated by sharp cargo edges or vehicle anchor points during use.

- Surface Treatment Technology: We apply specialized resin coatings and heat treatment processes to the webbing surface, creating an extra layer of protection. This coating not only boosts abrasion resistance but also enhances water repellency and dirt resistance.

- Comprehensive Quality Control: With over 8,000 sqm of production space and advanced automated lines, SMK achieves full-process quality control from raw material to finished goods. Beyond the webbing's intrinsic resistance, we prioritize supplying complementary wear sleeves and corner protectors, offering customers a complete solution for both cargo and strap protection.

Summary: SMK's Commitment to Quality

Choosing a 2-inch ratchet strap means choosing a guarantee for transport safety. The polyester webbing provided by Zhangjiagang SMK MFG. Co., Ltd. offers: low elongation for rock-solid cargo securing; high weather resistance to adapt to global climate challenges; and superior abrasion resistance for a longer service life and higher return on investment. Combined with our compliance through C-TPAT anti-terrorism inspections, SMETA audits, and multiple GS and patent certifications, we provide not just products, but an efficient, safe, and compliant global supply chain solution. Whether choosing our XSTRAP brand or utilizing flexible OEM/ODM customization services, SMK is dedicated to delivering high-quality, efficient cargo control systems.

How Do the Design Details of the Ratchet Mechanism in 2-Inch Tie-Down Straps Define Their Durability and Ease of Operation?

In professional cargo securing, the core value of the 2-inch ratchet strap lies in the significant tension and precise release control it provides. The key to achieving all this is the design and manufacturing precision of the Ratchet Mechanism. For B2B customers demanding safety, efficiency, and longevity, understanding the structural characteristics of the ratchet mechanism is crucial for evaluating product quality and manufacturer competence.

Since its founding in 2002, Zhangjiagang SMK MFG. Co., Ltd. (SMK) has focused on the R&D and export of cargo control products. Utilizing over 20 years of industry experience, we recognize that a superior ratchet mechanism is the "heart" that guarantees the reliability of the entire cargo control system. Below, we detail how SMK optimizes the ratchet mechanism—covering gear structure, handle design, material selection, and manufacturing precision—to deliver industry-leading products.

I. Gear and Pawl Structure Design: Determining the Durability Limit

The essence of the ratchet mechanism lies in the engagement of the gear and the pawl. This determines the maximum load the strap can withstand and its service life.

- Gear Pitch and Thickness: SMK's ratchet mechanisms feature a precisely engineered Fine-Tooth Pitch design. Finer gearing means that when tension is applied, the force is distributed more evenly across multiple teeth, significantly reducing stress concentration on individual teeth and greatly improving the mechanism's fatigue resistance and durability under the Working Load Limit (WLL). Material Strength: We use high-strength, heat-treated carbon or alloy steel for the gears, ensuring their hardness and toughness can withstand repeated, high-intensity tensile impacts.

- Pawl and Riveting Process: In designing the pawl, SMK focuses on achieving a perfect engagement angle with the gear to prevent slipping or skipping during tightening and tension retention. Manufacturing Advantage: Our factory, with over 8,000 sqm of production space and advanced automated lines, allows us to use high-pressure, precise automated riveting processes for critical connection points (like rivets) on the ratchet and pawl, eliminating play and ensuring the mechanism maintains its original strength and reliability after thousands of operational cycles.

II. Ergonomic Handle Design: Enhancing Operational Efficiency and Comfort

For professional users who frequently load and unload cargo, the design of the ratchet handle directly impacts their efficiency and safety.

- Leverage and Mechanical Advantage: SMK's ratchet handles are engineered with a precise mechanical balance to provide the optimal lever arm length. This allows the operator to generate a higher Standard Tension Force (STF) with less Hand Force, easily meeting the requirements for professional cargo securing. Ease of Operation: The handle's smooth opening and closing mechanism is optimized to ensure that when tension release is required, the operator can quickly and safely open the release lever, avoiding unnecessary jamming or the safety hazards of sudden release.

- Handle Material and Grip: Our handles are typically covered with durable, ergonomically shaped plastic or composite materials, enhancing slip resistance and comfort when operating with wet hands or gloves, maintaining a good user experience even in extreme cold or heat. This is a key reason why SMK's brand XSTRAP is favored by professional logistics customers globally.

III. Anti-Corrosion Treatment of Materials: Ensuring Long-Term Service Life

As metal components, ratchet mechanisms must resist corrosion from moisture, salt spray, and chemicals, as rust can lead to functional failure.

- Multi-Layer Protective Coating: SMK's metal components are typically treated with high-standard Zinc Plating or Powder Coating. These coatings not only provide superior corrosion resistance but also comply with environmental regulations.

- Advantage of In-House Testing Labs: In our internal testing labs, all metal components undergo rigorous Salt Spray Testing to ensure that the mechanism's smoothness and reliability are unaffected by harsh transport environments, especially during sea freight and coastal operations.

Summary: SMK's Technical Commitment

A superior 2-inch ratchet mechanism reflects a professional manufacturer's technical depth and commitment to quality. Zhangjiagang SMK MFG. Co., Ltd. offers: precise gear structure for outstanding durability; optimized handle design for high efficiency and ease of operation; and strict anti-corrosion treatment for extended product lifespan. Through ISO 9001 certification, C-TPAT inspection, and multiple GS certifications, we demonstrate our command over every detail and our adherence to global supply chain standards. Whether supplying standard XSTRAP products or performing in-depth OEM/ODM customization, SMK is dedicated to delivering safe, efficient, and reliable cargo control solutions.

What are the Potential Dangers of Overtightening 2-Inch Tie-Down Straps to Both the Cargo and the Webbing During Actual Transport?

In the heavy-duty transport and logistics industry, ensuring secure Cargo Securing is paramount. Many operators mistakenly believe "tighter means safer" and thus overtighten 2-inch ratchet straps. However, this seemingly cautious action is actually a hidden killer of safety and durability for both the cargo and the strap itself.

As a global manufacturer with over 20 years of R&D experience in cargo control products since 2002, Zhangjiagang SMK MFG. Co., Ltd. (SMK) is committed to promoting correct cargo securing practices and providing safety-compliant products. We know that the 2-inch strap only achieves maximum safety effectiveness when applying the "just right" tension force.

Below, we detail the potential hazards of overtightening from three professional perspectives: cargo damage, webbing and hardware fatigue, and safety compliance.

I. Direct Damage to the Secured Cargo (Cargo Damage)

The excessive tension generated by overtightening directly threatens the integrity of the cargo, leading to unnecessary losses and claim risks.

- Structural Deformation and Breakage: The ratchet mechanism can generate a powerful Standard Tension Force (STF). When this exceeds the pressure tolerance limit of the cargo—especially wooden crates, cardboard boxes, glassware, or light machinery—overtightening can directly cause cargo edges to collapse, casings to crack, or internal structures to be damaged. Zhangjiagang SMK MFG. Co., Ltd. (SMK)'s products are widely used in transportation, logistics, and industrial sectors. Our high-performance webbing and ratchets are designed to efficiently transmit pre-tension, so we strongly advise customers to set a tightening limit based on the cargo's crush capacity to avoid losses due to manual over-operation.

- Surface Scratches and Functional Damage: For high-value goods like finished machinery or vehicles, overtightening can cause the webbing to leave permanent indentations or scratches on the contact surface. Promotion of Solutions: SMK not only manufactures high-quality straps but also supplies and promotes the use of Corner Protectors and Wear Sleeves. These accessories effectively distribute the tension force while shielding the cargo surface from excessive pressure and friction damage. Our XSTRAP brand emphasizes the application of a complete cargo control system, rather than the brute force use of a single product.

II. Fatigue and Failure of the 2-Inch Strap and Hardware

Overtightening forces the strap to operate under tension far exceeding its design expectation, drastically shortening the product's lifespan and potentially causing sudden failure.

- Webbing Fiber Damage and Fatigue: Under extreme tension nearing its Breaking Strength (BS), the individual fiber filaments within the polyester webbing experience irreversible micro-damage and fracture. While a single overtightening incident may not cause immediate breakage, it accelerates the webbing's fatigue aging, making it more susceptible to failure during subsequent normal use. Tensile Deformation: Even high-quality, low-elongation polyester can experience additional stretch under excessive tension, impairing its elastic recovery and reducing its ability to maintain tension over time.

- Stress Concentration on Ratchet Mechanism and Hardware: The gears and pawls in the ratchet mechanism are critical load-bearing points. Overtightening subjects these metal components to extreme stress, accelerating gear wear, deformation, and loosening of the rivets. Threat to Anchor Points: The end fittings (like hooks) and the vehicle's connection anchor points also endure excessive pull from overtightening, potentially causing permanent hook bending or vehicle anchor point tearing, which directly leads to catastrophic safety failures. SMK's Quality Assurance: We use our ISO 9001 certification and in-house testing labs to conduct strict WLL and fatigue testing on the metal components of the ratchet mechanism. The heat-treated steel and precise riveting processes we employ ensure the product can handle its rated working load, but any operation exceeding the WLL endangers safety.

III. Compliance with Safety Regulations and Requirements

Correct tension is not just a technical issue; it's a matter of compliance required by global logistics transport regulations (such as FMCSA or EN 12195-2).

- Erosion of Safety Factor: The strap's Working Load Limit (WLL) is typically set at one-third of its Breaking Strength (i.e., a 3:1 safety factor). Overtightening directly erodes this safety margin, pushing the product near or above its WLL. The risk of breakage increases exponentially when encountering sudden impacts or emergency braking during transit.

As a company that has passed C-TPAT anti-terrorism inspections and SMETA audits, SMK prioritizes safety compliance. We are dedicated to providing high-quality, compliant, and easy-to-use cargo control systems and educating customers to use professional Tension Meters to ensure the applied tension is accurate, safe, and compliant.

In conclusion, the art of professional cargo securing lies in balance. Choosing high-quality 2-inch ratchet straps from Zhangjiagang SMK MFG. Co., Ltd., combined with correct tightening procedures, is the only way to achieve the optimal combination of cargo securing efficiency and transport safety.

What are the Core Competitive Advantages of the 2-Inch Ratchet Strap in Terms of Efficiency, Cargo Protection, and Operational Safety?

In global transport, logistics, outdoor, and industrial sectors, cargo securing technology has undergone a revolution. Historically, cumbersome chains, wire ropes, or easily loosening natural fiber ropes were the norm. Today, the high-strength, highly efficient 2-Inch Ratchet Straps have rapidly established their status as the industry standard.

As a professional manufacturer and global exporter with over 20 years of experience in cargo control products since 2002, Zhangjiagang SMK MFG. Co., Ltd. (SMK) deeply understands the core drivers behind this shift. The advantages of the 2-inch ratchet strap go beyond simply being "good to use"; they represent a systematic superiority over traditional fastening methods (such as ropes and chains) in Efficiency, Cargo Protection, and Operational Safety.

Below, we will detail how the 2-inch ratchet straps produced by SMK create greater value for global customers across three core dimensions.

I. Extreme Operational Efficiency: Saving Time and Labor

In the fast-paced logistics industry, the speed of loading and unloading directly translates into economic benefits. The 2-inch ratchet strap demonstrates unparalleled efficiency advantages.

- Rapid Tightening and Release: Compared to ropes that require complex knotting and manual tension, or chains that require heavy-duty tools, the ratchet mechanism offers a mechanically assisted tightening method. The operator simply pumps the ratchet handle to quickly stretch the webbing to the required Standard Tension Force (STF). Professional Design Advantage: SMK's ratchet mechanisms are precision-engineered with ergonomic optimization, ensuring smooth and effortless handle operation. When releasing tension, the scientifically designed release lever allows for quick and safe unlocking, significantly reducing loading and unloading cycles, which is especially beneficial for logistics fleets requiring frequent securing.

- Lightweight and Easy to Store: Weight Advantage: High-strength polyester webbing is significantly lighter than chains of the same Working Load Limit (WLL). This reduces operator physical strain and vehicle dead weight, marginally improving payload efficiency. SMK's Global Supply Chain Advantage: We operate three factories and a large-scale warehouse center, forming an efficient international supply network. This means we can consistently provide high-quality, lightweight 2-inch straps, helping global customers operate efficiently.

II. Excellent Cargo Protection Capability: Reducing Damage and Claims

This is the most significant advantage of the 2-inch strap over metal restraints, directly impacting customer cargo integrity and brand reputation.

- Flexible Contact Surface and Even Pressure: Non-Invasive Securing: Polyester webbing is soft and flat, allowing it to distribute pressure evenly upon contact with the cargo. It avoids the sharp point contact of chains or wire ropes, preventing dents, scratches, or structural crush damage to the cargo surface. SMK's Product Accessories: Zhangjiagang SMK MFG. Co., Ltd. not only manufactures quality webbing but also supplies a full range of cargo control accessories, such as wear sleeves and corner protectors. When used with 2-inch straps, these accessories further protect the edges and surfaces of sensitive cargo (like wood, glass, or custom machinery).

- Stable, Low-Elongation Characteristics: Polyester Stability: The polyester fiber used by SMK features extremely low elongation. This means that once tightened, the strap maintains a stable pre-tension throughout the transit, effectively resisting loosening caused by vibration and impact. This minimizes the possibility of cargo movement, fundamentally safeguarding its integrity.

III. Unmatched Operational Safety: Compliance and Personnel Protection

Safety is the cornerstone of SMK's products, and we ensure the highest safety standards through product design and process control.

- Clear Load Identification and Compliance: WLL Transparency: Every 2-inch strap leaving SMK's factory features clear, durable labels indicating the Working Load Limit (WLL) and Breaking Strength (BS). This allows operators to easily calculate loads, avoiding the risk of overloading based on estimation, and ensures compliance with multiple requirements including GS certification and international regulations. SMK's Quality System: We are ISO 9001 certified and follow strict quality control procedures. We have in-house testing labs to conduct full-process quality control on every batch of ratchets and webbing, guaranteeing reliable and true product performance metrics.

- Reduced Operational Risk: No Recoil Risk: Ropes or chains can cause dangerous recoil if they break under heavy load. Ratchet straps are designed for a gradual release of tension, and polyester material tends to simply break rather than violently recoil when failing.