Since its establishment in 2002,

Zhangjiagang SMK MFG. Co., Ltd.

has specialized in cargo securing and control products, with over 20 years of experience in R&D and global export. The company is China Endless Ratchet Strap Manufacturers and OEM Retractable Ratchet Strap Factory, and operates three factories and a large-scale warehouse center, forming an efficient international supply network.

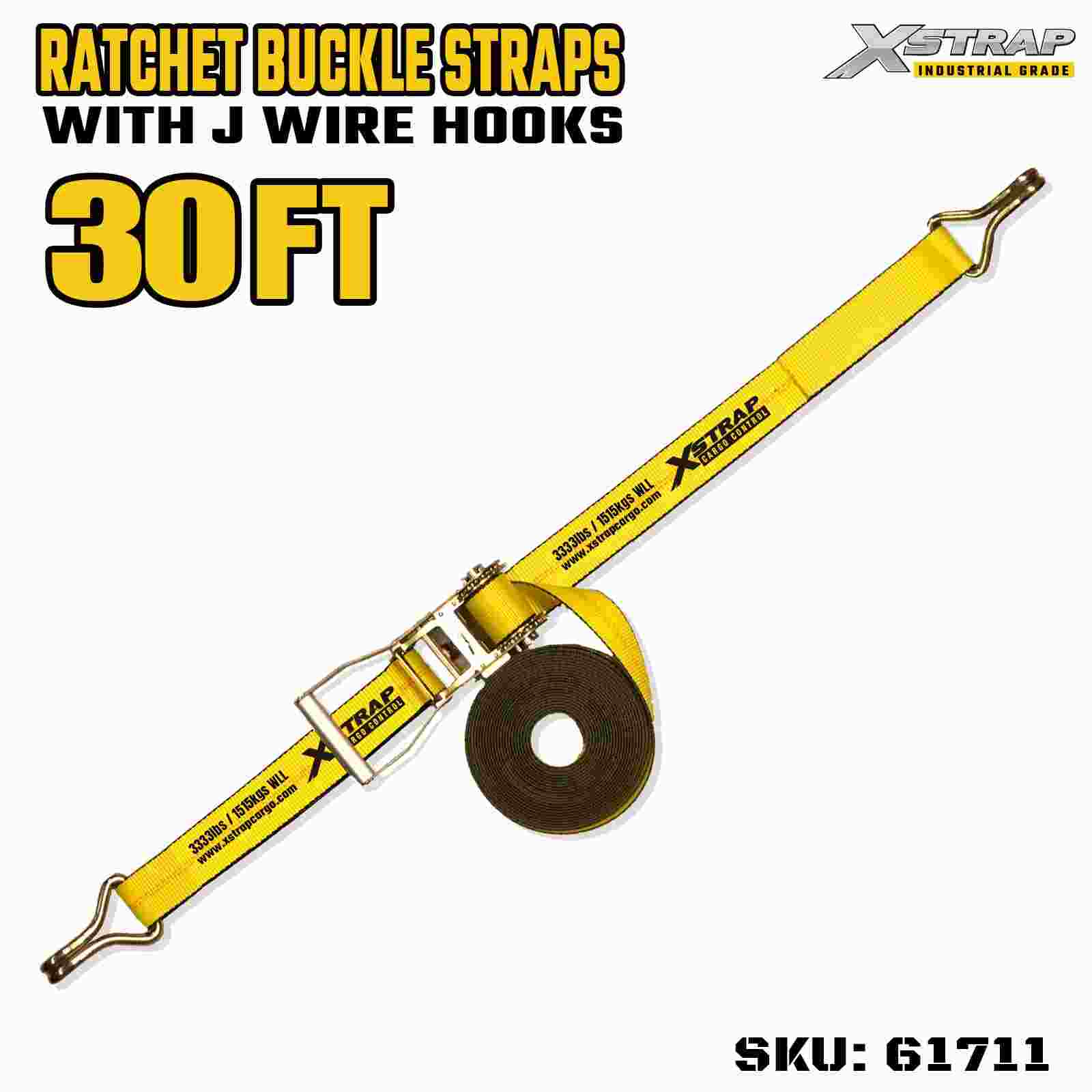

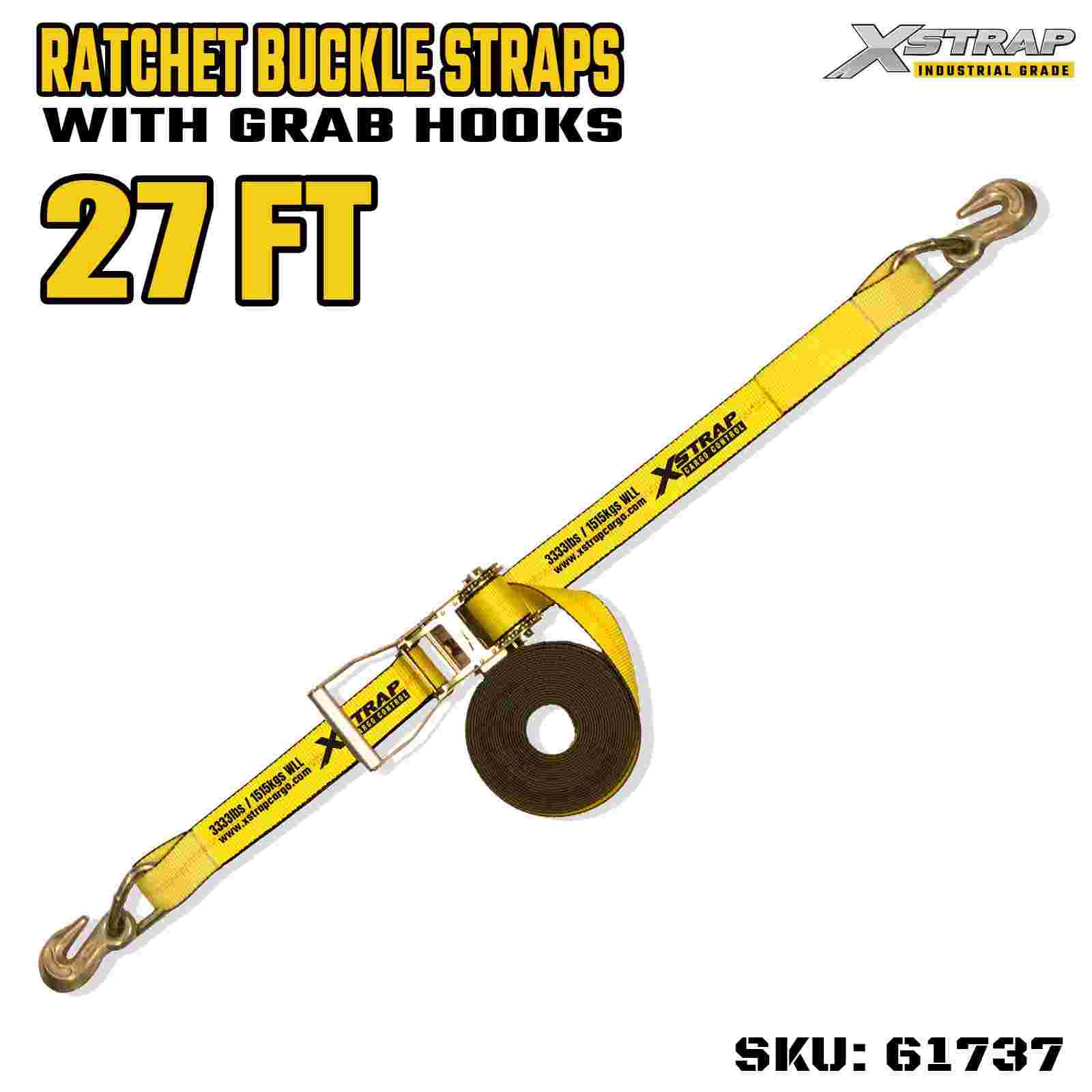

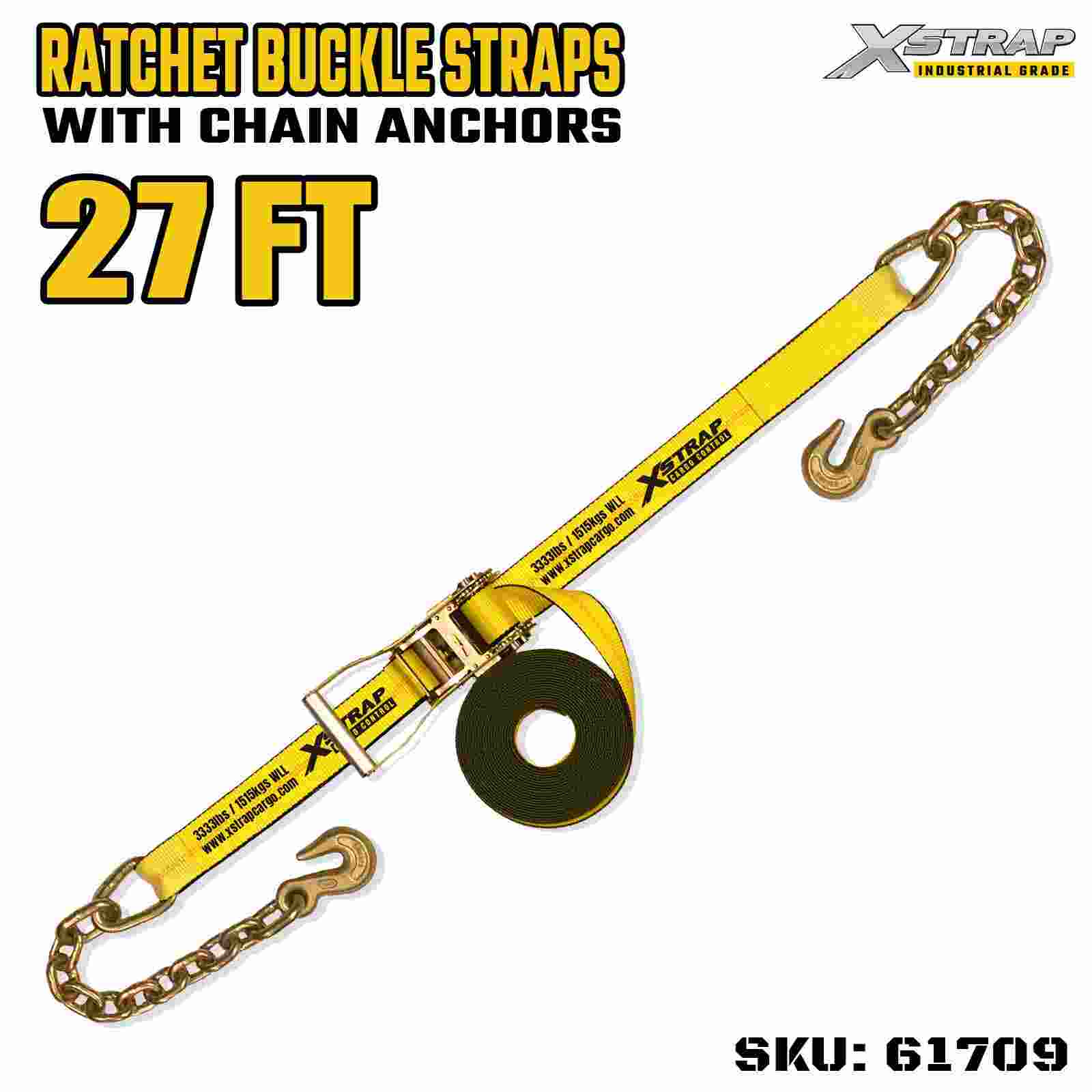

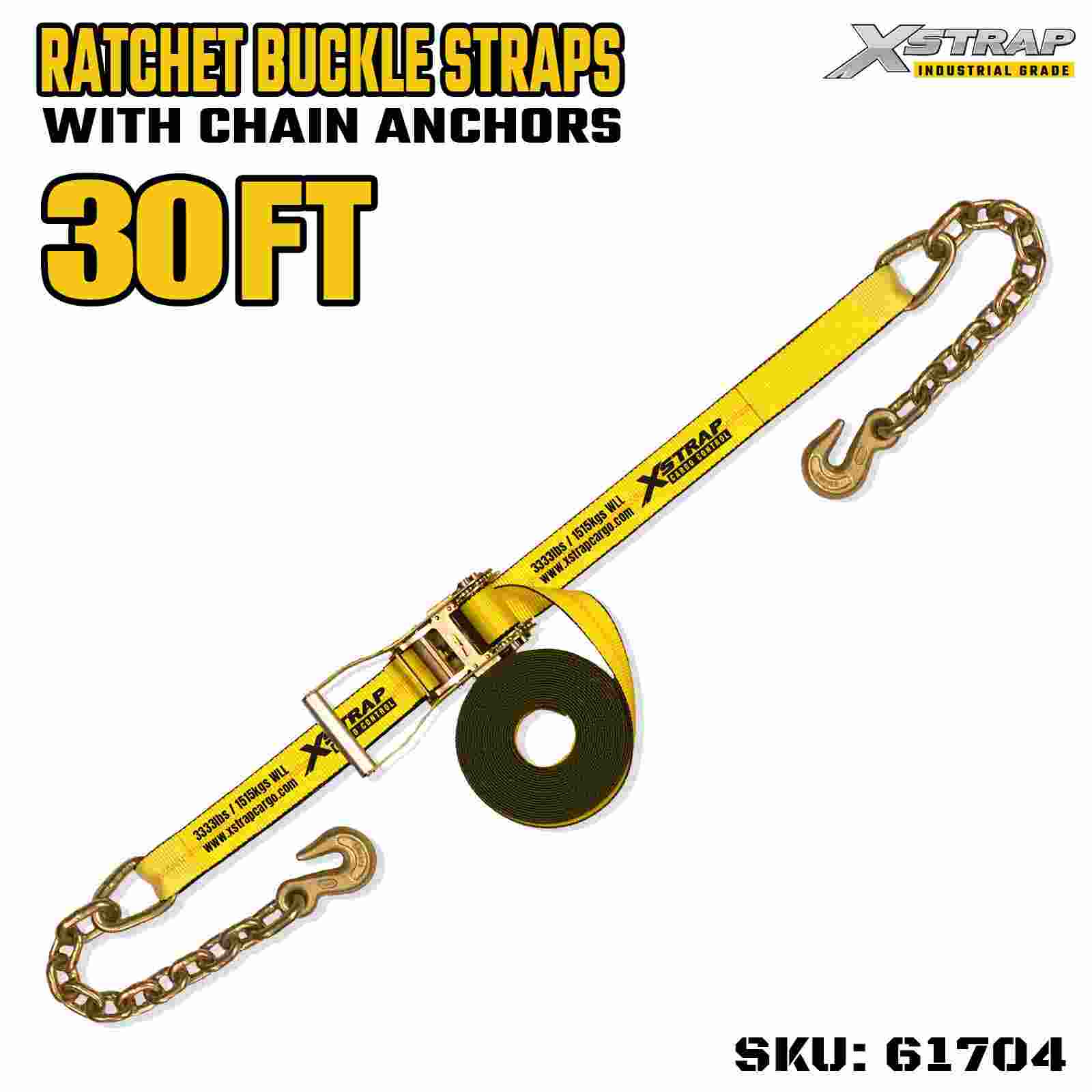

SMK's product range includes tie-down straps, bungee cords, tow straps, lifting slings, hoists, and 4x4 accessories, widely used in transportation, logistics, outdoor, and industrial sectors. Its in-house brand XSTRAP enjoys strong recognition in global markets, alongside flexible OEM/ODM services for customized needs.

With over 8,000 sqm of production space, SMK is equipped with advanced automated lines and in-house testing labs, ensuring full-process quality control from raw material to finished goods. The company is ISO 9001 certified, SMETA audited, and has passed C-TPAT anti-terrorism inspections and multiple GS and patent certifications.

Looking ahead, SMK will continue to upgrade its cargo control systems, stay close to customer needs, and provide high-quality, efficient products and services worldwide.

Product

-

New Products

- Flatbed Solutions

- Interior Van Solutions

- Utility Tie down and Bungee Cord

- Auto Transport and Towing Solutions

- Lifting Solutions

- Tie Down Hardware

-

TUV&GS Certificated Tie Down and Bungee Cord

-

Towing & Rigging

-

4×4 Off-Road & Trailers

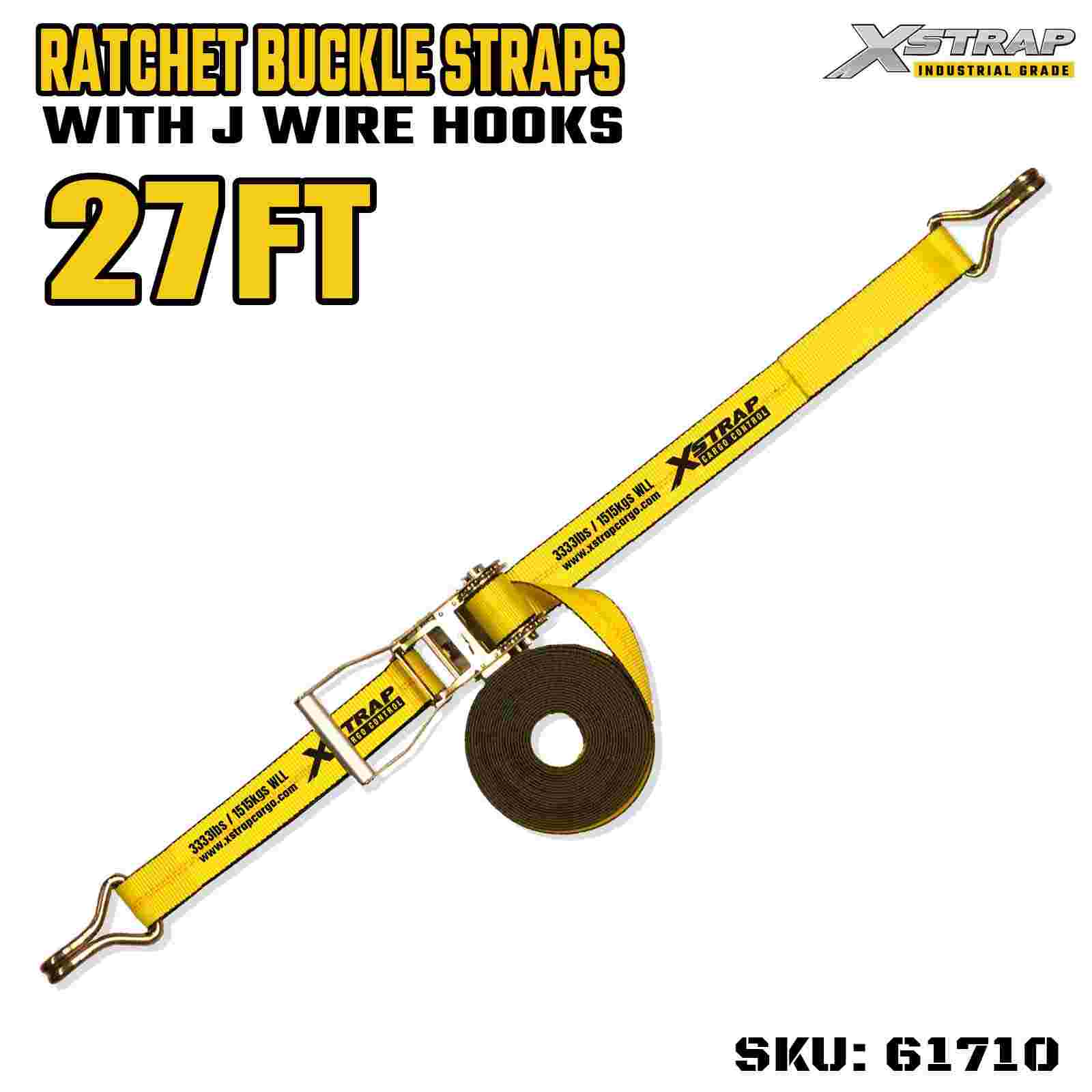

Wholesale and manufactures of endless retractable ratchet strap industrial grade

-

Understanding the Role of Tow Dolly Basket Straps in Vehicle Transport In the field of vehicle transport, Tow Dolly Basket Straps are recognized as one of the safest and most stable securing tools ava...

READ MORE -

1. Understanding the Role of Chain Binders in Load Securement In the world of heavy transportation, Chain Binders are essential tools for ensuring cargo stability. They utilize either a lever principl...

READ MORE -

Understanding the Role of Car Tie Down Straps in Vehicle Transport Safety is the primary consideration when transporting a vehicle. Although standard cargo straps may look similar to Car Tie Down Stra...

READ MORE -

In the field of cargo transportation, securing loads is crucial to ensure the safety of both the cargo and the vehicle. Over the years, ratchet straps have been widely used to secure loads. However, w...

READ MORE

Core Advantages of Endless Retractable Ratchet Strap Compared to Ordinary Ratchet Straps

Since its establishment in 2002, Zhangjiagang SMK MFG. Co., Ltd. has specialized in cargo securing and control products, with over 20 years of experience in R&D and global export. The company operates three factories and a large-scale warehouse center, forming an efficient international supply network.

SMK's product range includes tie-down straps, bungee cords, tow straps, lifting slings, hoists, and 4x4 accessories, widely used in transportation, logistics, outdoor, and industrial sectors. Its in-house brand XSTRAP enjoys strong recognition in global markets, alongside flexible OEM/ODM services for customized needs.

With over 8,000 sqm of production space, SMK is equipped with advanced automated lines and in-house testing labs, ensuring full-process quality control from raw material to finished goods. The company is ISO 9001 certified, SMETA audited, and has passed C-TPAT anti-terrorism inspections and multiple GS and patent certifications.

Looking ahead, SMK will continue to upgrade its cargo control systems, stay close to customer needs, and provide high-quality, efficient products and services worldwide.

Among its wide range of products, the Endless Retractable Ratchet Strap stands out for its innovative design and advanced mechanical performance. Compared with ordinary ratchet straps, it provides greater flexibility, safety, and efficiency in various heavy-duty applications.

1. Continuous Adjustment and Infinite Length Design

Traditional ratchet straps usually have fixed or limited adjustment ranges, making it difficult to handle irregular cargo sizes. The Endless Retractable Ratchet Strap features an infinite adjustable loop design, allowing users to freely adjust the webbing without the limitation of hooks or endpoints. This not only improves versatility but also ensures a more balanced force distribution on the load surface.

2. Higher Efficiency and Easier Operation

The retractable mechanism allows the strap to automatically wind and tighten, eliminating excess slack and simplifying operation. It helps workers reduce repetitive manual actions, shorten loading times, and maintain consistent tension throughout the process. SMK’s R&D team has optimized the gear structure and spring tension to ensure smoother retraction, increasing both safety and working efficiency.

3. Enhanced Safety and Reliability

Endless Retractable Ratchet Straps produced by SMK are made of high-strength polyester or nylon webbing with reinforced stitching. They provide superior tensile strength and abrasion resistance. The internal ratchet system features anti-recoil protection and double locking teeth to prevent accidental loosening under vibration or shock. This ensures stable cargo control even in harsh conditions such as long-distance transportation, marine environments, or outdoor use.

4. Long Service Life and Lower Maintenance Costs

All SMK Endless Retractable Ratchet Straps are tested under strict laboratory conditions to guarantee long-lasting durability. The automatic retractable system reduces wear caused by improper handling, while corrosion-resistant materials extend service life. This combination of design and quality makes it an ideal choice for industrial and commercial use where reliability is crucial.

How the Stretch and Retraction Mechanism of Endless Retractable Ratchet Strap Is Designed

The stretch and retraction mechanism of the Endless Retractable Ratchet Strap is one of its most critical innovations. Its internal structure integrates a precision spring recoil system and multi-tooth locking gears, designed to provide smooth and balanced tension during both tightening and releasing operations.

1. Internal Structural Design

Inside the ratchet housing, a high-strength steel spring coil provides the elastic force necessary for automatic retraction. When the handle is operated, the spindle rotates and gradually winds the webbing. Once released, the stored energy in the spring retracts the strap in a controlled motion, preventing sudden recoil or tangling. SMK engineers designed the mechanism with an optimized torque ratio, ensuring steady force and smooth operation even under heavy loads.

2. Material and Durability

The ratchet gears and spindle are made from hardened alloy steel with anti-corrosion coatings. The spring material is fatigue-tested to withstand thousands of operational cycles without loss of elasticity. The webbing passes through an anodized metal guide that minimizes friction and protects the fiber structure during retraction. These design elements ensure long-term stability and resistance to wear, suitable for industrial and outdoor environments.

3. Safety Mechanisms

To prevent misoperation, the Endless Retractable Ratchet Strap is equipped with a manual lock system that allows users to secure or release the retraction function at any time. This ensures precise tension control and prevents the strap from snapping back unexpectedly. The ergonomic handle also features an anti-slip grip to enhance comfort and safety during use.

4. Testing and Certification

Every Endless Retractable Ratchet Strap manufactured by SMK undergoes rigorous quality testing, including tensile strength, fatigue, and environmental exposure tests. The company’s in-house laboratory ensures that each batch meets ISO 9001, SMETA, and GS certification standards. These strict controls guarantee the consistent performance of the retraction mechanism over time.

How to Use Endless Retractable Ratchet Strap to Secure Heavy Machinery or Cargo

Securing large machinery or heavy cargo requires high-strength equipment capable of maintaining consistent tension and preventing movement during transport. The Endless Retractable Ratchet Strap developed by Zhangjiagang SMK MFG. Co., Ltd. provides the ideal solution for this application, combining strong holding power with operational convenience.

1. Pre-Use Inspection

Before use, check the webbing and ratchet mechanism for any signs of wear, fraying, or deformation. Ensure the rated load capacity matches or exceeds the weight of the cargo. SMK offers Endless Retractable Ratchet Straps in various widths and load limits, allowing customers to select the most suitable product for their application.

2. Choosing Anchor Points

Securely attach the strap to structural anchor points on both the vehicle and the cargo. Avoid sharp edges that could damage the webbing. Use corner protectors or sleeves to maintain even pressure across the strap and prevent abrasion.

3. Tightening Process

- Thread the webbing through the ratchet’s central spindle and ensure it lies flat.

- Wrap the strap around the cargo and feed it through the slot without twists.

- Operate the handle until the strap is evenly tightened across the load surface.

- Engage the locking system to secure the ratchet in place.

4. During Transport

Once the cargo is secured, check the strap tension after 10–15 minutes of travel to ensure it remains stable. SMK’s retractable design automatically compensates for minor vibration-induced slack, maintaining consistent load pressure throughout transit.

5. After Use

After unloading, slowly release the ratchet handle and allow the strap to retract automatically. Wipe off dust or oil residues, and store the strap in a dry, ventilated place to extend its service life. Regular inspection and proper storage will maximize performance and safety.

How to Adjust and Maintain the Ratchet System When Endless Retractable Ratchet Strap Tightness Is Uneven

Uneven tension in an Endless Retractable Ratchet Strap can affect load stability and reduce safety during transportation. Zhangjiagang SMK MFG. Co., Ltd. provides the following professional adjustment and maintenance guidelines to ensure that the ratchet system performs optimally and maintains long-term reliability.

1. Common Causes of Uneven Tension

- Webbing Twisting or Overlap: Improper retraction or overlapping layers can create tension differences.

- Worn Ratchet Teeth: Continuous use may lead to partial engagement of gear teeth, reducing grip.

- Spring Fatigue: Reduced elasticity from repeated cycles can affect consistent retraction force.

- Dust or Contamination: Accumulated debris or rust can hinder smooth operation of the ratchet system.

2. Adjustment Steps

- Release the Lock: Disengage the ratchet handle and fully loosen the webbing.

- Check Alignment: Straighten the strap, ensuring it lays flat with no twists or overlaps.

- Rewind the Strap: Feed the strap evenly onto the drum while manually guiding it into position.

- Tighten Evenly: Apply uniform tension on both sides while operating the handle.

- Stability Test: Shake the load slightly to confirm balanced tension before transport.

3. Maintenance Guidelines

- Cleaning: After each use, remove dirt and debris with a dry cloth. Avoid soaking in water.

- Lubrication: Apply anti-rust lubricant on gear pivots and the rotating spindle every few months.

- Corrosion Protection: Use corrosion-resistant ratchet assemblies for humid or marine environments.

- Regular Inspection: Conduct a full system check every six months, replacing any damaged parts immediately.

4. Technical Reliability and Support

SMK’s Endless Retractable Ratchet Strap adopts a modular ratchet structure, allowing for easy disassembly, maintenance, and part replacement. Every product undergoes rigorous performance testing before shipment, including load, fatigue, and corrosion resistance assessments. Supported by ISO 9001 certification and advanced automated testing facilities, SMK ensures consistent quality and long service life across all models.