Since its establishment in 2002,

Zhangjiagang SMK MFG. Co., Ltd.

has specialized in cargo securing and control products, with over 20 years of experience in R&D and global export. The company is China Cam and Ratchet Buckles Manufacturers and Custom Cam and Ratchet Buckles Suppliers, and operates three factories and a large-scale warehouse center, forming an efficient international supply network.

SMK's product range includes tie-down straps, bungee cords, tow straps, lifting slings, hoists, and 4x4 accessories, widely used in transportation, logistics, outdoor, and industrial sectors. Its in-house brand XSTRAP enjoys strong recognition in global markets, alongside flexible OEM/ODM services for customized needs.

With over 8,000 sqm of production space, SMK is equipped with advanced automated lines and in-house testing labs, ensuring full-process quality control from raw material to finished goods. The company is ISO 9001 certified, SMETA audited, and has passed C-TPAT anti-terrorism inspections and multiple GS and patent certifications.

Looking ahead, SMK will continue to upgrade its cargo control systems, stay close to customer needs, and provide high-quality, efficient products and services worldwide.

Product

-

New Products

- Flatbed Solutions

- Interior Van Solutions

- Utility Tie down and Bungee Cord

- Auto Transport and Towing Solutions

- Lifting Solutions

- Tie Down Hardware

-

TUV&GS Certificated Tie Down and Bungee Cord

-

Towing & Rigging

-

4×4 Off-Road & Trailers

Wholesale and manufactures of Cam and Ratchet Buckles

-

Understanding the Role of Tow Dolly Basket Straps in Vehicle Transport In the field of vehicle transport, Tow Dolly Basket Straps are recognized as one of the safest and most stable securing tools ava...

READ MORE -

1. Understanding the Role of Chain Binders in Load Securement In the world of heavy transportation, Chain Binders are essential tools for ensuring cargo stability. They utilize either a lever principl...

READ MORE -

Understanding the Role of Car Tie Down Straps in Vehicle Transport Safety is the primary consideration when transporting a vehicle. Although standard cargo straps may look similar to Car Tie Down Stra...

READ MORE -

In the field of cargo transportation, securing loads is crucial to ensure the safety of both the cargo and the vehicle. Over the years, ratchet straps have been widely used to secure loads. However, w...

READ MORE

How do you properly tighten and release cam and ratchet buckles?

Introduction to Cam and Ratchet Buckles

Cam and ratchet buckles are widely used in cargo securing and load control applications, providing adjustable tension and reliable fastening for a variety of transport and industrial needs. Companies like Zhangjiagang SMK MFG. Co., Ltd., with over 20 years of experience in manufacturing cargo securing products, produce cam and ratchet buckles as part of their XSTRAP brand, ensuring quality, durability, and compliance with international standards. Understanding the proper methods to tighten and release these buckles is essential for safe and efficient operation in sectors such as logistics, transportation, and industrial handling.

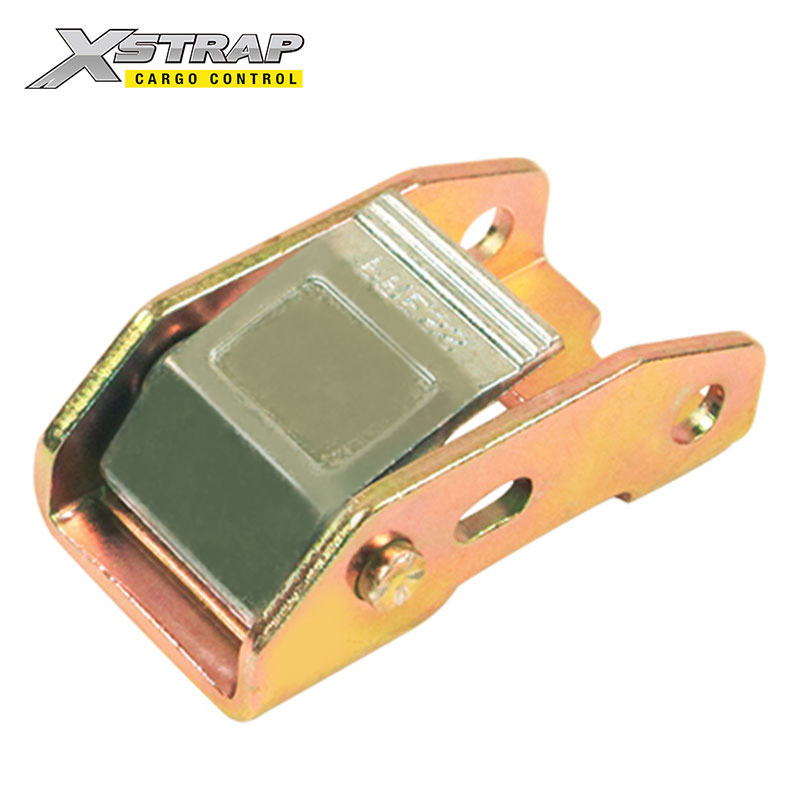

Understanding Cam Buckles

Cam buckles use a spring-loaded mechanism that grips the webbing strap when tension is applied. They are ideal for light to medium load securing, providing quick adjustment without the need for tools. The cam lever engages the strap and prevents it from slipping backward, holding the load firmly in place. SMK incorporates high-strength materials and precision mechanisms to ensure that cam buckles function consistently under various conditions. Proper use involves threading the strap through the cam, pulling it tight manually, and checking that the lever securely grips the strap.

Proper Tightening of Cam Buckles

To properly tighten a cam buckle, the strap must be threaded through the buckle in the correct orientation. The loose end is pulled through the cam mechanism while holding the buckle firmly against the load. The spring inside the cam lever grips the strap automatically, preventing slippage. Users should gradually increase tension until the load is secure, ensuring that the strap remains aligned and free from twists or kinks. SMK’s quality control ensures that cam buckles maintain reliable tension and grip throughout repeated use, making them suitable for transporting various cargo sizes and weights.

Releasing Cam Buckles Safely

Releasing a cam buckle involves pressing the lever to disengage the gripping mechanism, allowing the strap to move freely. It is important to release tension gradually to prevent sudden movement of the load. Operators should maintain control of the strap end to avoid snapping or rapid recoil, which could damage the strap or cause injury. SMK’s designs consider user ergonomics, ensuring that the lever operates smoothly and consistently, reducing the risk of accidental release while maintaining ease of use.

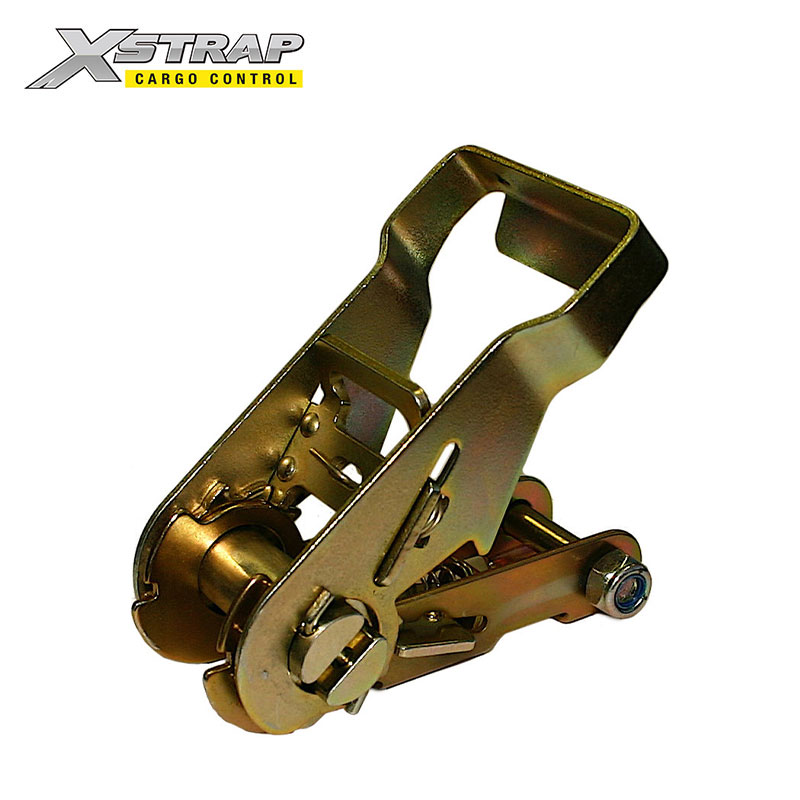

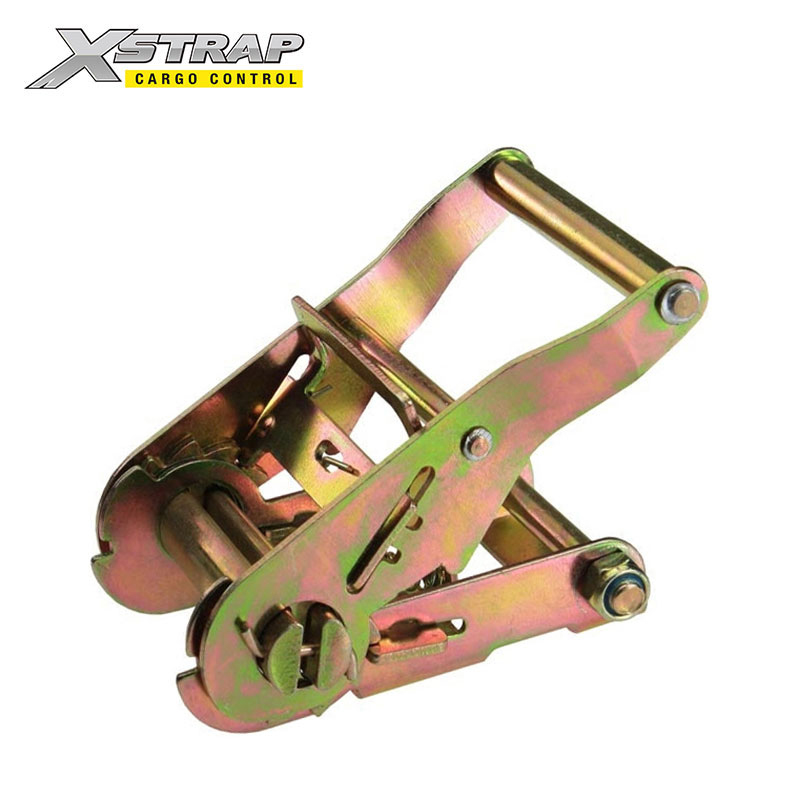

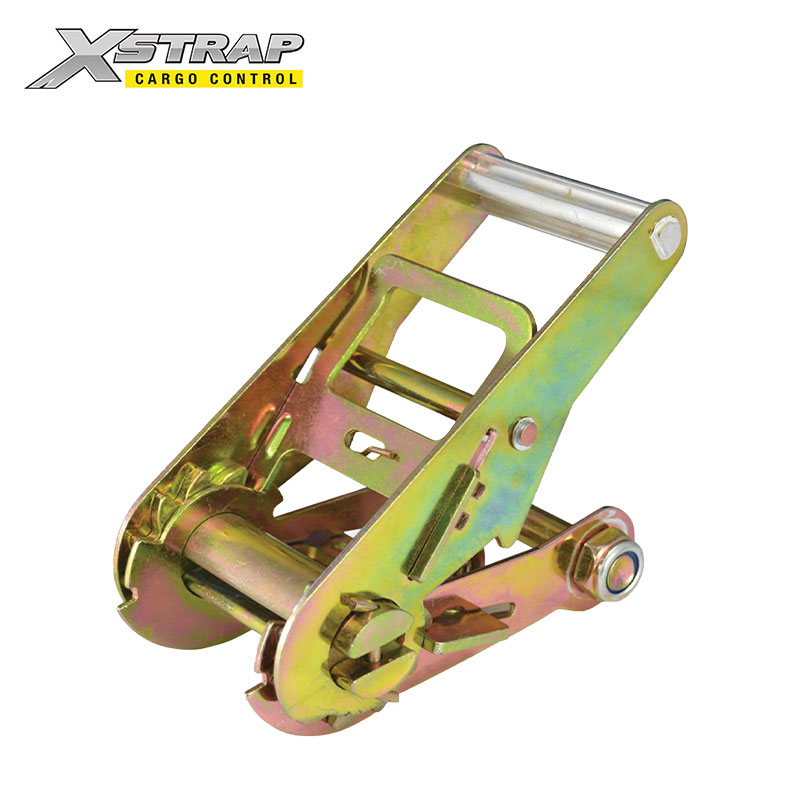

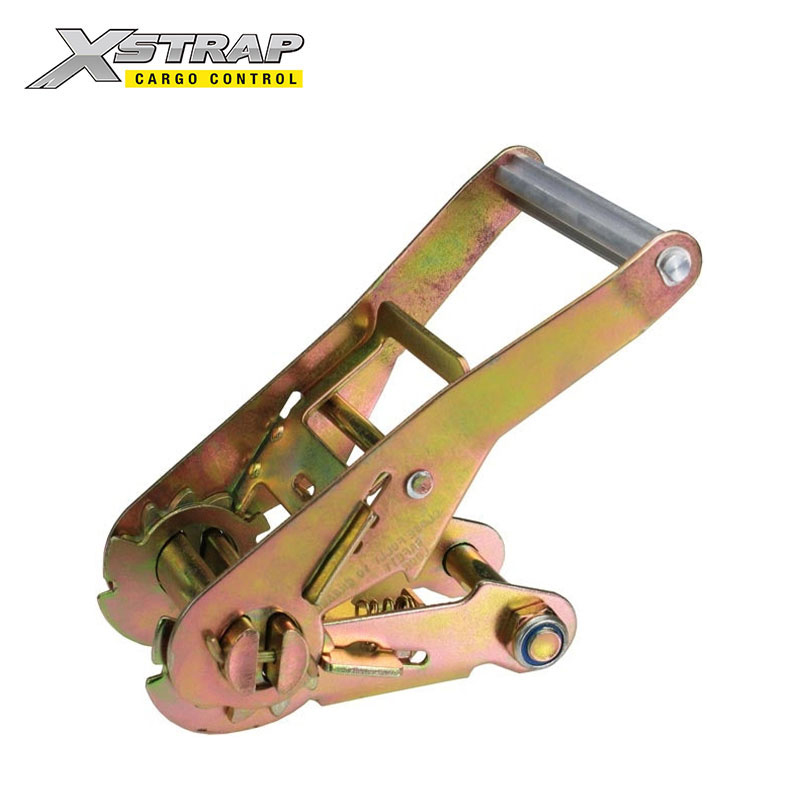

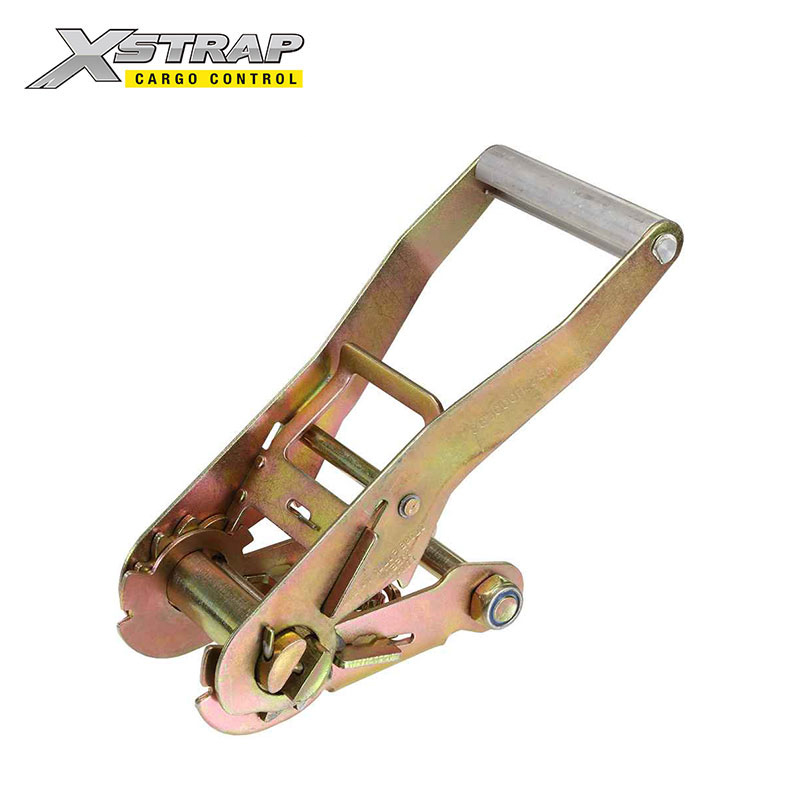

Understanding Ratchet Buckles

Ratchet buckles are designed for higher load capacities and long-distance tensioning. They use a ratcheting mechanism with a handle and gear system to incrementally tighten the strap around the load. The ratchet allows precise control over tension and prevents the strap from loosening under vibration or movement. SMK produces ratchet buckles with durable components, including corrosion-resistant metals and reinforced straps, to ensure performance in demanding industrial and transportation environments. Ratchet buckles are especially effective for securing vehicles, machinery, or large cargo on trucks, trailers, and shipping containers.

Proper Tightening of Ratchet Buckles

To tighten a ratchet buckle, the strap is first threaded through the ratchet spool and pulled manually to remove slack. The handle is then pumped back and forth, rotating the spool and gradually increasing tension on the strap. The ratchet mechanism ensures incremental tightening, allowing the operator to reach the desired tension without excessive force. SMK ensures that ratchet buckles have smooth operation, minimal backlash, and consistent gear engagement, enabling operators to achieve secure tension with controlled effort. Users should check that the strap is evenly tensioned and free from twists, as uneven load distribution can compromise stability.

Releasing Ratchet Buckles Safely

Releasing a ratchet buckle requires disengaging the locking pawl, which prevents the strap from unwinding. The handle is lifted to release the pawl, and the spool is allowed to rotate gradually while maintaining control of the strap. This controlled release prevents sudden recoil, reducing the risk of injury or damage to the cargo. SMK designs ratchet mechanisms with ergonomics and safety in mind, ensuring that the release is predictable and manageable even under heavy tension. Proper handling involves maintaining grip on the strap and avoiding rapid unwinding, particularly when the strap is under load.

Comparison of Cam and Ratchet Buckles

The following table summarizes key differences in operation and performance between cam and ratchet buckles:

| Feature | Cam Buckle | Ratchet Buckle |

|---|---|---|

| Load Capacity | Light to medium | Medium to heavy |

| Tightening Method | Manual pull through lever | Ratchet handle and gear mechanism |

| Release Method | Press lever gradually | Disengage pawl and control spool rotation |

| Speed of Adjustment | Fast, suitable for quick loads | Slower, allows precise tensioning |

| Typical Use | Securing lightweight cargo, camping gear | Securing vehicles, heavy industrial loads |

Industrial Applications of Cam and Ratchet Buckles

Cam and ratchet buckles serve different purposes depending on load type and operational environment. Cam buckles are preferred for lighter cargo, such as packages, luggage, or camping equipment, where rapid adjustment is beneficial. Ratchet buckles are essential for heavy-duty applications, including securing vehicles on trailers, industrial machinery, or large shipments. SMK’s wide product range and global distribution allow users to select the appropriate buckle type based on operational needs, ensuring safe and efficient load management.

Maintenance and Longevity

Regular maintenance is crucial for both cam and ratchet buckles. Cam buckles should be inspected for wear, spring fatigue, and dirt accumulation that could affect gripping. Ratchet buckles require lubrication of the gear mechanism and inspection for corrosion or metal fatigue. SMK provides guidelines and in-house quality testing to ensure that all buckles maintain consistent performance over time. Proper maintenance prolongs the life of the buckle and enhances safety in repeated or continuous use.

Ergonomic Considerations

Both cam and ratchet buckles are designed with ergonomics in mind. Cam buckles feature levers that are easy to press and manipulate, reducing hand strain during repeated use. Ratchet buckles incorporate handle designs that allow incremental tightening with manageable force, even under heavy loads. SMK’s emphasis on ergonomic design ensures that operators can perform tightening and releasing operations efficiently and safely, minimizing fatigue and the risk of errors.

Training and Best Practices

Proper training is essential for safe and efficient use of cam and ratchet buckles. Users should be instructed on correct threading, tensioning, and controlled release techniques. Observing strap alignment, avoiding twists, and maintaining a clear line of sight to the load are critical for operational safety. SMK supports its products with guidelines and recommendations to ensure that operators understand best practices for both cam and ratchet buckle usage in different industrial and transport applications.

Integration with Cargo Securing Systems

Cam and ratchet buckles are part of comprehensive cargo securing solutions, often used in combination with tie-down straps, bungee cords, and lifting slings. SMK’s XSTRAP brand provides a complete system where buckles are compatible with other securing accessories, allowing flexible and reliable load control. Proper tightening and releasing procedures are essential to maintain system integrity and ensure that all components work together safely and efficiently.

Table of Operational Guidelines

The following table provides a summary of best practices for tightening and releasing cam and ratchet buckles:

| Aspect | Cam Buckle | Ratchet Buckle |

|---|---|---|

| Tightening | Thread strap through lever, pull manually, ensure strap is straight | Thread strap through spool, pump handle gradually, check tension evenly |

| Releasing | Press lever gradually, control strap end to prevent recoil | Disengage pawl, rotate spool slowly, maintain control of strap |

| Inspection | Check for spring function and lever wear | Check gears, pawl, and handle for wear and lubrication |

| Safety Check | Ensure strap is aligned and free of twists | Ensure strap runs smoothly and handle functions properly |

Conclusion on Usage

Proper tightening and releasing of cam and ratchet buckles ensures secure load handling and operational safety. By following manufacturer guidelines and industry best practices, operators can maintain the integrity of cargo securing systems while reducing the risk of accidents. SMK MFG. Co., Ltd.’s focus on high-quality materials, in-house testing, and ergonomic design supports effective and reliable use of these buckles across transportation, logistics, and industrial applications worldwide.

Can cam and ratchet buckles be used outdoors or in humid environments for a long time?

Durability of Cam and Ratchet Buckles in Outdoor Environments

Cam and ratchet buckles are widely used for securing cargo in transportation, logistics, and outdoor activities. Their construction must withstand a range of environmental conditions, including prolonged exposure to moisture, sunlight, and fluctuating temperatures. Zhangjiagang SMK MFG. Co., Ltd. emphasizes the use of high-quality materials and corrosion-resistant coatings in its cam and ratchet buckles to ensure that they maintain functionality and safety even when used outdoors or in humid environments for extended periods. This design focus allows operators to rely on these buckles for long-term cargo securing applications without frequent replacement.

Material Selection for Outdoor Use

The materials used in cam and ratchet buckles are critical in determining their performance in outdoor and humid environments. Metals such as stainless steel or zinc-plated steel provide resistance to rust and corrosion, while high-strength polymers can withstand UV exposure without degrading. SMK incorporates careful material selection in its XSTRAP products, ensuring that both the metallic and plastic components can endure outdoor conditions. Properly treated metals resist oxidation, and durable polymers prevent brittleness or cracking, extending the usable life of the buckle under prolonged exposure.

Resistance to Moisture and Humidity

Moisture and high humidity can affect both cam and ratchet buckles if materials are not adequately protected. Water exposure can cause rust in untreated metal parts and reduce the mechanical performance of springs and gears. SMK mitigates these risks by using corrosion-resistant coatings and testing components under simulated humid conditions. The anti-corrosion treatments maintain smooth operation of the cam lever and ratchet mechanism, ensuring that outdoor or marine cargo applications can rely on consistent performance without mechanical failure over time.

UV and Weather Exposure

Continuous exposure to sunlight can degrade some polymers and fabrics used in straps and buckles. SMK selects UV-stabilized plastics for cam buckles and incorporates protective coatings on metal ratchet mechanisms to reduce the impact of prolonged sunlight exposure. By combining materials with weather-resistant properties and rigorous testing, SMK ensures that the buckles retain functionality and strength even under direct sunlight or in variable weather conditions. This makes them suitable for outdoor use in transport vehicles, trailers, or camping and recreational applications.

Maintenance Practices for Longevity

Regular maintenance is necessary to extend the lifespan of cam and ratchet buckles used outdoors or in humid environments. Metal components should be inspected for rust or corrosion and lubricated as needed, particularly in ratchet mechanisms that involve gears and moving parts. Polymer and plastic components should be checked for signs of UV degradation, cracking, or wear. SMK provides guidance for routine maintenance to ensure that all buckles continue to operate effectively, maintaining tension and load security under extended environmental exposure.

Performance Testing in Varied Conditions

SMK leverages in-house testing labs to evaluate buckle performance under simulated outdoor and humid conditions. Tests include prolonged exposure to moisture, temperature cycling, UV radiation, and load retention trials. These assessments confirm that both cam and ratchet buckles maintain reliable operation, gripping strength, and mechanical integrity even after extended use in challenging environments. Such testing provides assurance that XSTRAP products meet the demands of outdoor transport, logistics, and industrial applications globally.

Impact of Continuous Load in Humid Environments

Long-term tension on a strap in humid or wet conditions can accelerate wear if the buckle materials are not adequately resistant. Cam buckles rely on spring mechanisms that must retain tension, while ratchet buckles depend on gears and pawls that must remain functional under load. SMK addresses this by using corrosion-resistant metals, reinforced plastics, and precision engineering to prevent weakening of the buckle under continuous tension. This ensures that both types of buckles remain reliable in securing loads during prolonged outdoor operations.

Comparison of Cam and Ratchet Buckle Suitability for Outdoor Use

The following table summarizes the relative suitability of cam and ratchet buckles for outdoor or humid environments:

| Feature | Cam Buckle | Ratchet Buckle |

|---|---|---|

| Material | High-strength polymers, corrosion-resistant metal lever | Metal gears and pawls with anti-corrosion treatment |

| Resistance to Moisture | Moderate, requires occasional inspection | High, suitable for heavy-duty outdoor use |

| UV Exposure | UV-stabilized plastics for strap and lever | Metal ratchet components coated for sunlight resistance |

| Maintenance | Inspect for wear and spring function | Lubricate gears, check for corrosion or deformation |

| Load Capacity | Light to medium | Medium to heavy |

Best Practices for Outdoor Use

To maximize the longevity of cam and ratchet buckles outdoors, operators should ensure proper storage when not in use, avoid prolonged exposure to water accumulation, and perform regular cleaning to remove dirt and salt residues. Straps should also be inspected for signs of mildew or weakening due to environmental factors. SMK provides detailed usage guidelines for both buckle types, emphasizing proper handling, tensioning, and environmental care to maintain safety and performance over time.

Integration with Cargo Systems in Humid or Outdoor Conditions

Cam and ratchet buckles are typically used in conjunction with tie-down straps, bungee cords, and lifting slings to secure loads in various transportation and industrial applications. SMK ensures that all components of the cargo securing system are compatible and resistant to environmental stress, allowing operators to rely on a complete system even in humid or outdoor conditions. This integrated approach enhances safety, reduces the risk of material failure, and ensures consistent load control for long-duration operations.

Customization for Environmental Resistance

SMK offers OEM and ODM options for customers requiring enhanced environmental resistance. Customizations may include upgraded coatings, stainless steel components, reinforced polymer levers, or specialized straps treated for UV and moisture protection. This flexibility allows industries such as marine transport, construction, and outdoor logistics to select buckles that are tailored to specific conditions, ensuring durability and functionality over prolonged periods of outdoor or humid exposure.

Inspection and Replacement Guidelines

Regular inspection is essential for long-term outdoor use. Operators should check metal parts for signs of rust, corrosion, or wear, and ensure polymer components remain free of cracks or brittleness. Any components showing significant degradation should be replaced immediately to maintain load security. SMK provides guidelines and replacement recommendations to help users maintain optimal safety and operational performance, even under challenging environmental conditions.

Table of Maintenance Intervals and Procedures

| Component | Inspection Frequency | Maintenance Action |

|---|---|---|

| Cam Lever | Monthly | Check spring function, clean and remove debris |

| Ratchet Gears and Pawls | Monthly or before heavy load use | Lubricate, inspect for corrosion, ensure smooth operation |

| Straps | Weekly for outdoor use | Check for fraying, mildew, UV degradation |

| Hooks and Metal Hardware | Monthly | Check for rust, deformation, and structural integrity |

Conclusion on Long-Term Outdoor and Humid Use

Cam and ratchet buckles produced by SMK MFG. Co., Ltd. are designed with materials, coatings, and mechanisms that support long-term use in outdoor and humid environments. Proper material selection, rigorous testing, maintenance practices, and optional customization allow these buckles to maintain functionality, safety, and load security over extended periods. By following recommended handling and inspection guidelines, users can rely on cam and ratchet buckles for a wide range of applications in transportation, logistics, construction, and industrial operations, even under challenging environmental conditions.