Since its establishment in 2002,

Zhangjiagang SMK MFG. Co., Ltd.

has specialized in cargo securing and control products, with over 20 years of experience in R&D and global export. The company is China E Track Straps Manufacturers and Custom E Track Straps Suppliers, and operates three factories and a large-scale warehouse center, forming an efficient international supply network.

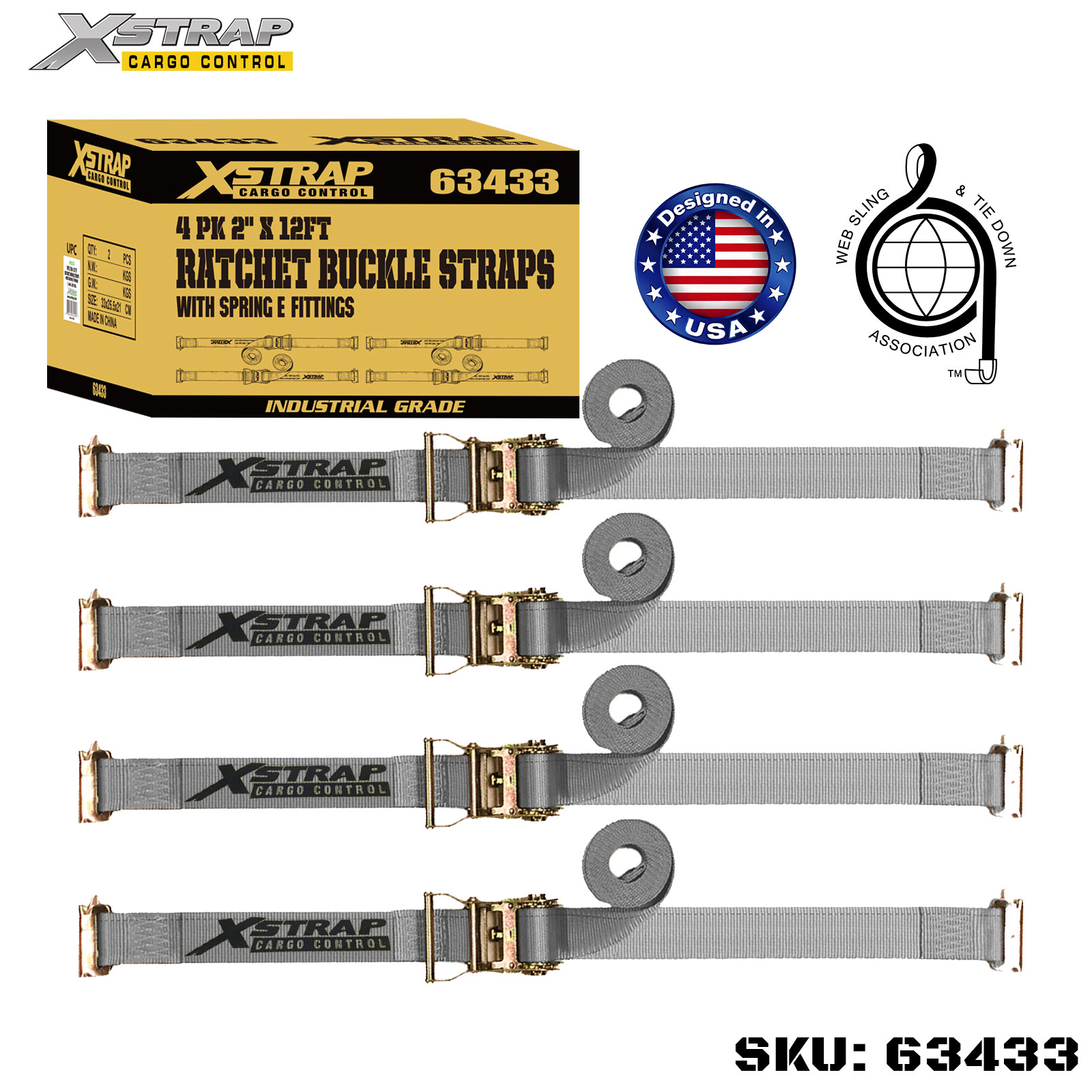

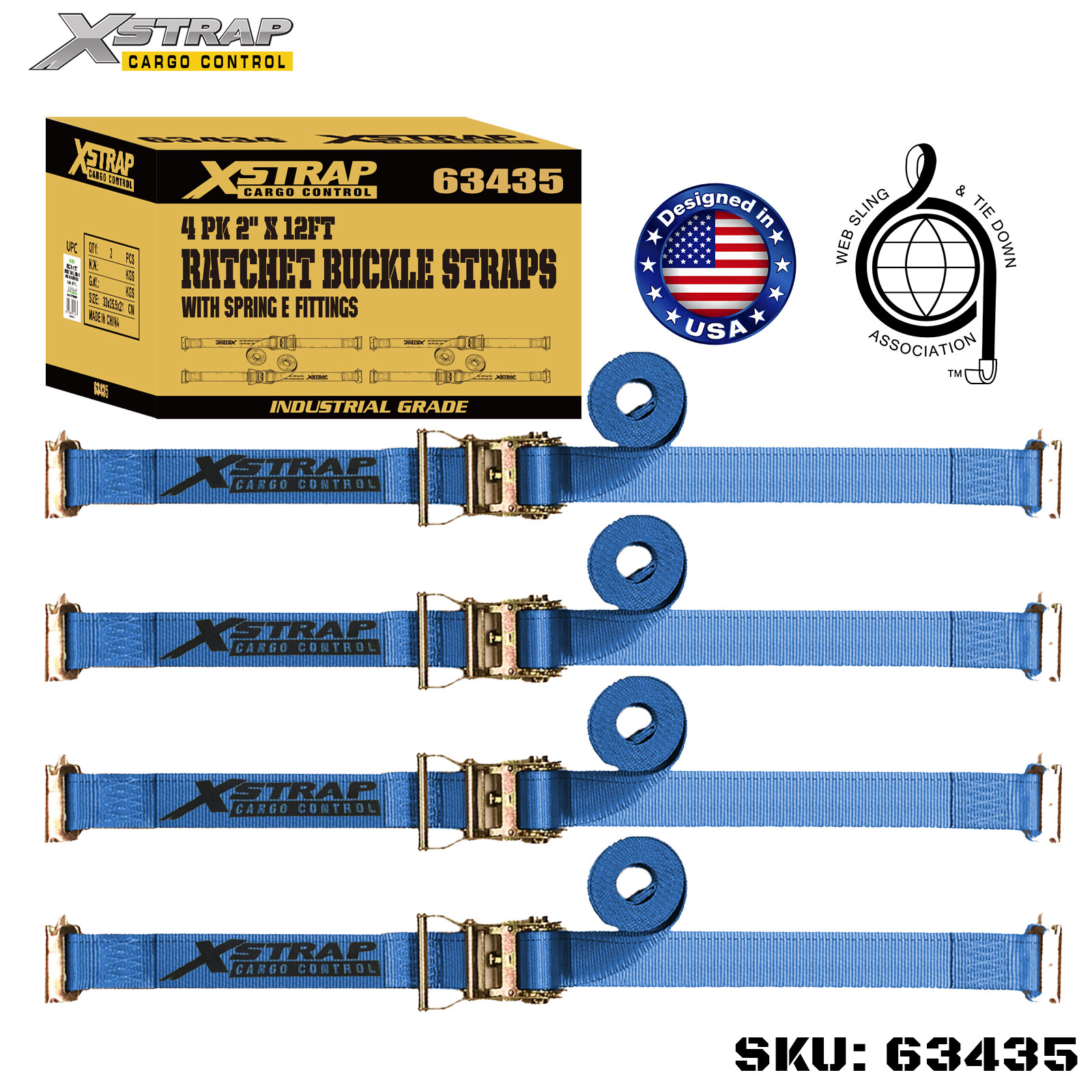

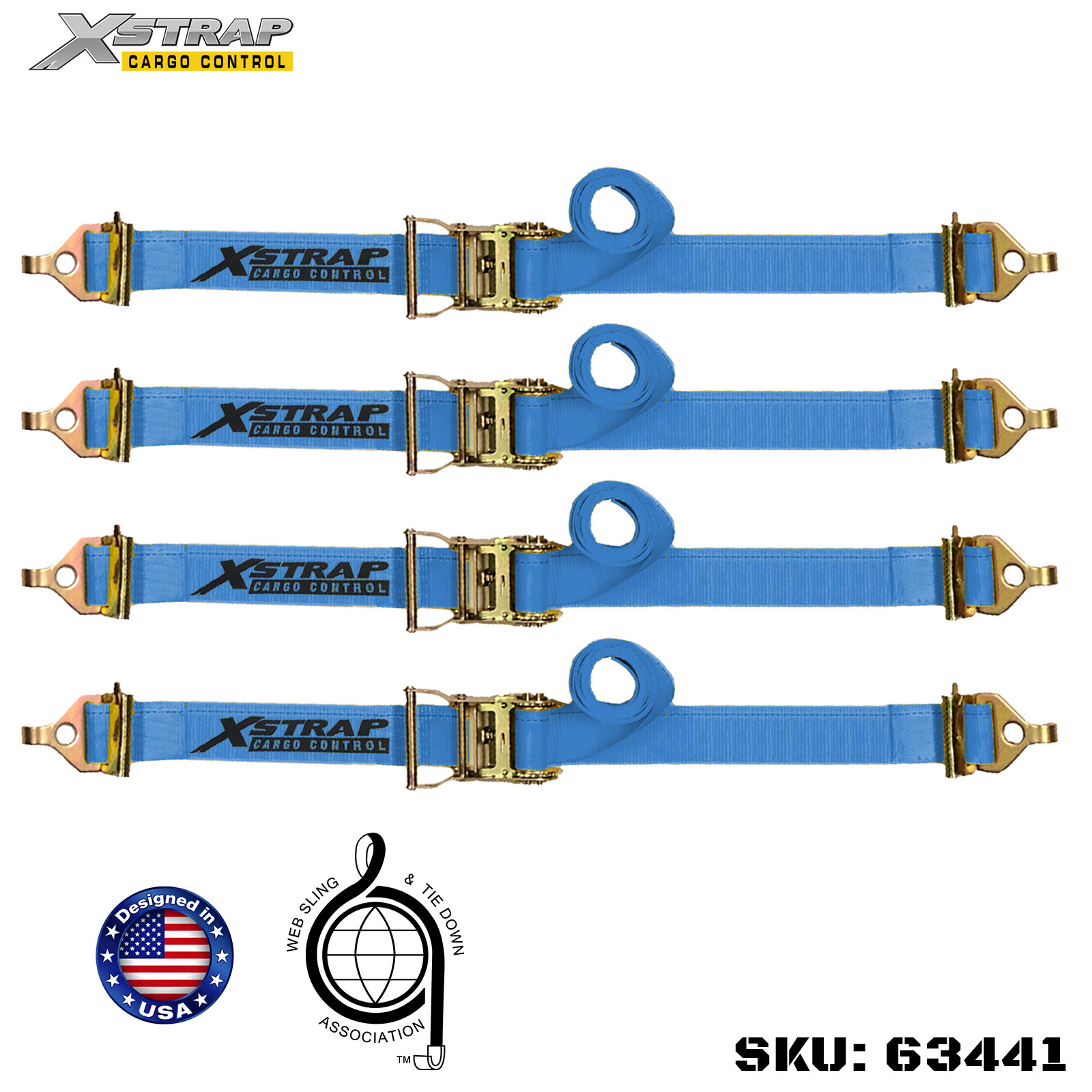

SMK's product range includes tie-down straps, bungee cords, tow straps, lifting slings, hoists, and 4x4 accessories, widely used in transportation, logistics, outdoor, and industrial sectors. Its in-house brand XSTRAP enjoys strong recognition in global markets, alongside flexible OEM/ODM services for customized needs.

With over 8,000 sqm of production space, SMK is equipped with advanced automated lines and in-house testing labs, ensuring full-process quality control from raw material to finished goods. The company is ISO 9001 certified, SMETA audited, and has passed C-TPAT anti-terrorism inspections and multiple GS and patent certifications.

Looking ahead, SMK will continue to upgrade its cargo control systems, stay close to customer needs, and provide high-quality, efficient products and services worldwide.

Product

-

New Products

- Flatbed Solutions

- Interior Van Solutions

- Utility Tie down and Bungee Cord

- Auto Transport and Towing Solutions

- Lifting Solutions

- Tie Down Hardware

-

TUV&GS Certificated Tie Down and Bungee Cord

-

Towing & Rigging

-

4×4 Off-Road & Trailers

Wholesale and manufactures of E Track Straps for interior van

-

Understanding the Role of Tow Dolly Basket Straps in Vehicle Transport In the field of vehicle transport, Tow Dolly Basket Straps are recognized as one of the safest and most stable securing tools ava...

READ MORE -

1. Understanding the Role of Chain Binders in Load Securement In the world of heavy transportation, Chain Binders are essential tools for ensuring cargo stability. They utilize either a lever principl...

READ MORE -

Understanding the Role of Car Tie Down Straps in Vehicle Transport Safety is the primary consideration when transporting a vehicle. Although standard cargo straps may look similar to Car Tie Down Stra...

READ MORE -

In the field of cargo transportation, securing loads is crucial to ensure the safety of both the cargo and the vehicle. Over the years, ratchet straps have been widely used to secure loads. However, w...

READ MORE

What are the Core Components of E Track Straps

E Track Straps are indispensable tools in modern freight transportation and securement. They are specifically designed to work with E-track or A-track rail systems, offering unparalleled flexibility and load capacity. As a specialized manufacturer deeply rooted in cargo control products since 2002, Zhangjiagang SMK MFG. Co., Ltd. applies stringent quality control and technical innovation to every core component of E Track Straps, backed by over two decades of R&D and global export experience.

A complete set of E Track Straps typically consists of the following three core components, which collectively determine the strap's safety, durability, and ease of use:

I. High-Strength Webbing

The webbing is the main body of the E Track Strap, bearing the primary tension and securing load. Its material, width, and strength are crucial factors determining the strap's performance.

1. Material Science and SMK Advantages:

- Material Selection: Our SMK (or in-house brand XSTRAP) E Track Straps primarily use high-tenacity Polyester webbing. Polyester is widely recognized for its excellent low stretch, abrasion resistance, and superior UV resistance. This ensures the strap maintains tension effectively during transit, even under harsh weather conditions, preventing cargo movement.

- Weaving Process: We utilize advanced automated production lines and strict weaving density control to ensure the thickness and uniformity of every strap meet leading industry standards. This directly relates to the webbing’s Working Load Limit (WLL) and Breaking Strength (BS).

- Water and Chemical Resistance Treatment: Considering the complexity of the logistics environment, Zhangjiagang SMK MFG. Co., Ltd. can provide specialized coatings to enhance the webbing's water resistance and anti-chemical corrosion capabilities, extending product life, especially for refrigerated transport or industrial applications.

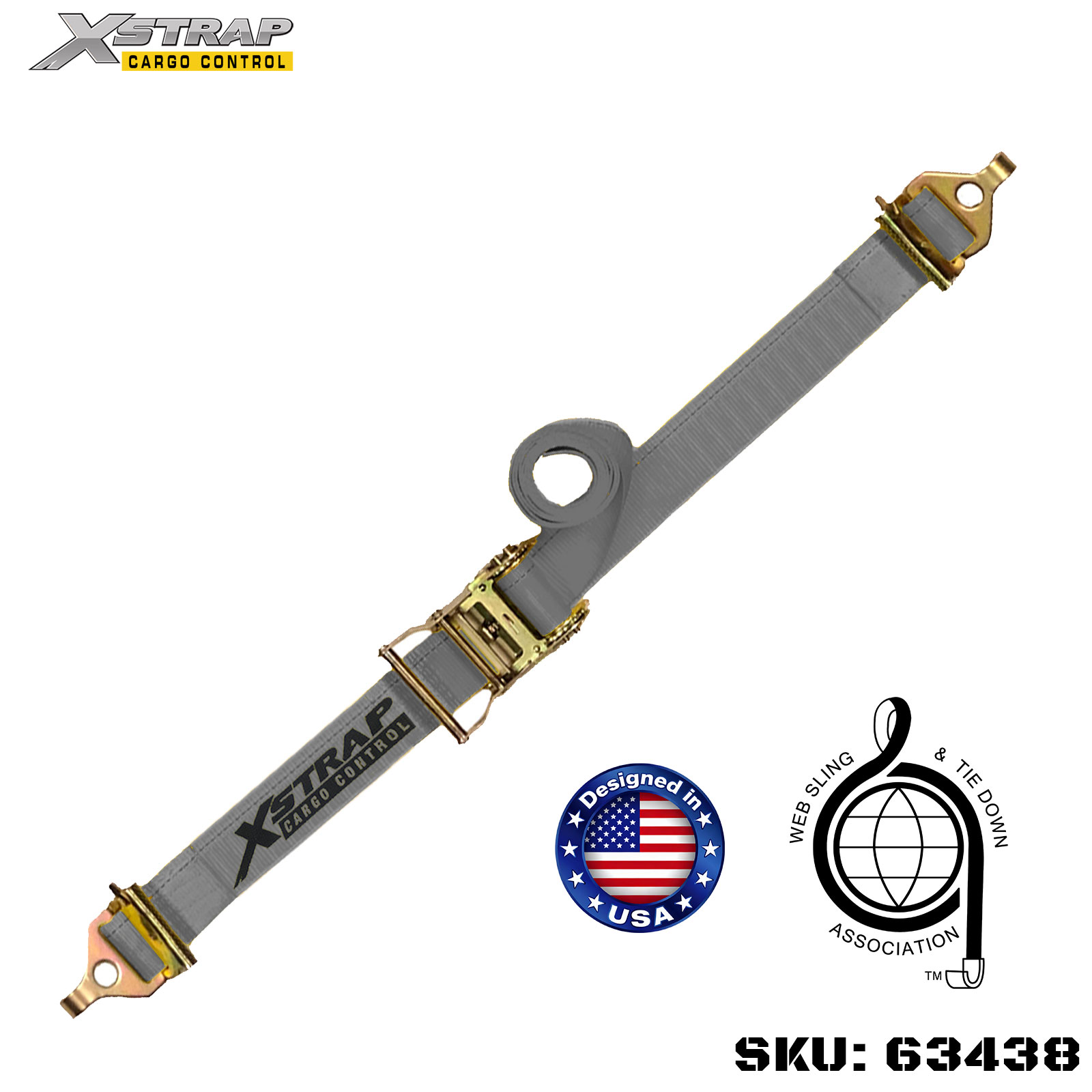

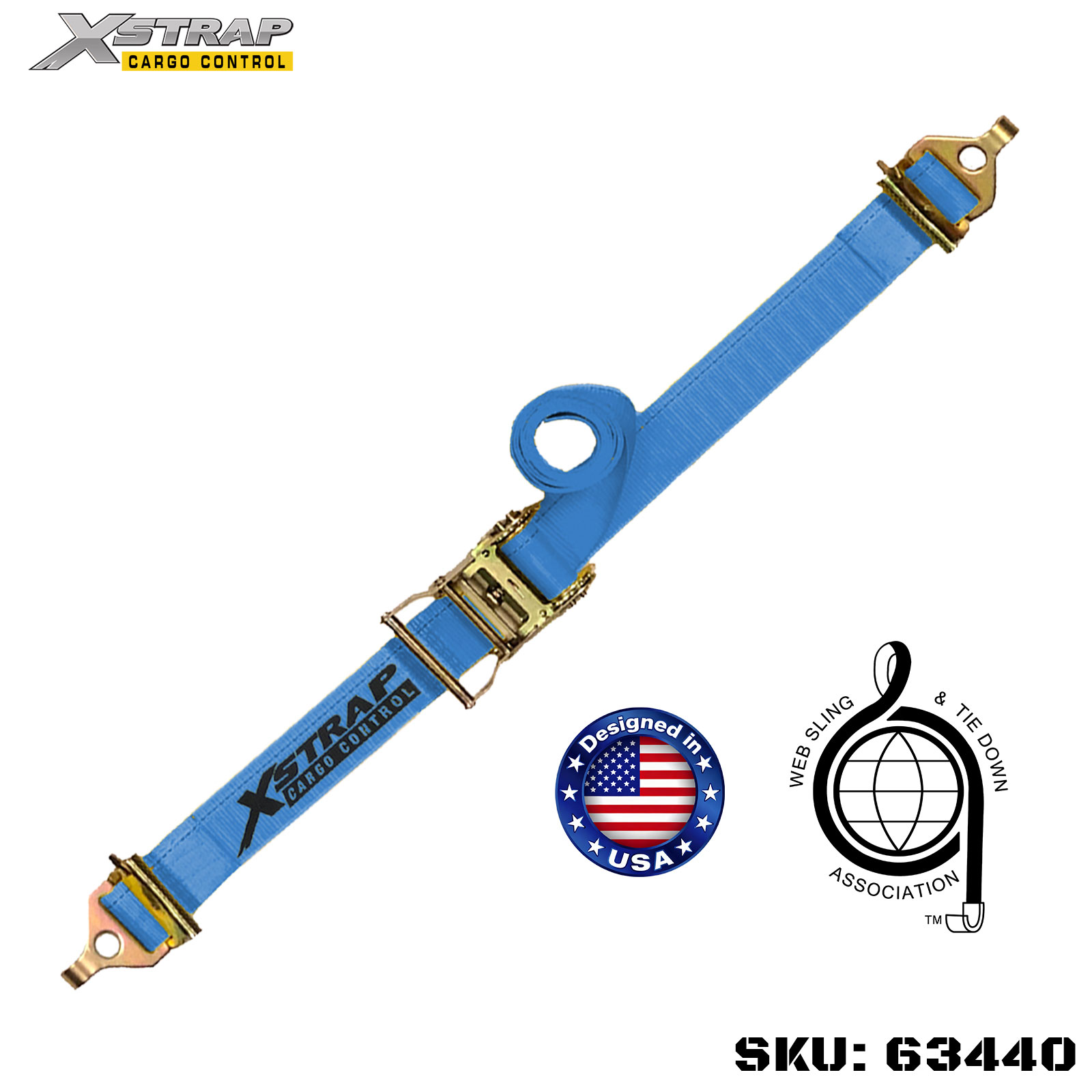

II. E-Fitting / End Fitting

The E-fitting is the bridge connecting the E Track Strap to the rail system. Its design and material directly impact the speed of installation and the reliability of the connection.

1. Design Types and Locking Mechanism:

- Standard Fitting: Common E-fittings are often the spring-loaded fitting type, allowing for quick insertion or removal from the track with a simple spring press. Fittings manufactured by SMK are precisely engineered to ensure perfect compatibility with all standard E-track or A-track systems, enabling fast attachment and detachment.

- Material and Strength: E-fittings are typically made from high-strength steel. As a manufacturer certified with ISO 9001 and audited for C-TPAT anti-terrorism inspection, SMK maintains rigorous standards for metal component selection, ensuring each fitting can withstand high loads without deformation.

- Surface Treatment: To resist moisture and corrosion, our fittings utilize high-quality Zinc Plated or Powder Coating finishes. This anti-rust treatment significantly enhances the fitting's durability, maintaining functionality even in harsh, high-salt environments.

III. Tensioning Device

The tensioning device is used to apply and maintain the necessary Pre-Tension on the webbing, making it a critical functional component for ensuring secure cargo fixation.

1. Ratchets and Cam Buckles:

- Ratchet Style: This is the most common tensioning method for heavy-duty applications. SMK’s ratchet mechanisms feature precision gear and handle design, allowing the operator to easily apply high-intensity pre-tension. We prioritize the ratchet's ergonomic design, with smooth and sturdy handles, ensuring safe and effort-saving operation.

- Cam Buckle Style: Suitable for light-duty or quick-tie scenarios. The cam buckles provided by Zhangjiagang SMK MFG. Co., Ltd. are simple to design, allowing quick tightening with a pull. They are convenient and fast, especially suitable for securing furniture or bulky but lighter-weight cargo.

- Safety and Testing: All our tensioning devices undergo strict cyclic testing and ultimate load testing in our company's in-house testing labs to ensure they do not fail or slip during long-term use. High-quality ratchet mechanisms are key to maintaining pre-tension at a safe and effective level, significantly mitigating transit risks.

What are the Application Differences between Ratchet and Cam Buckle Tensioners on E Track Straps

In the field of freight transport and securement, the choice of E Track Straps directly affects cargo safety and transport efficiency. The key factor determining the performance and applicable scenarios of E Track Straps is their tensioning device—specifically, the Ratchet tensioner and the Cam Buckle tensioner.

Since its establishment in 2002, Zhangjiagang SMK MFG. Co., Ltd. has focused on the R&D and manufacturing of cargo securing and control products. With over two decades of industry experience, we understand that providing the most suitable tensioning device solution for our clients is paramount. Our in-house brand XSTRAP product line reflects our deep understanding and sophisticated manufacturing process for both types of tensioners.

Below is a detailed professional analysis of the core differences, application scenarios, and SMK’s quality advantages concerning Ratchet and Cam Buckle tensioners on E Track Straps, helping B2B clients make the most optimized selection.

I. Ratchet Tensioner: The Industrial Choice for Heavy Loads and High Pre-Tension

The ratchet tensioner is the most common and widely applied type of E Track Strap, especially suitable for scenarios requiring high pre-tension and high load capacity.

1. Core Mechanism and Technical Advantages:

The ratchet mechanism translates the force applied by the operator on the handle into strong pulling force on the webbing through a set of precision gears and pawls. Its greatest feature is the mechanical advantage, capable of achieving pre-tension far beyond human manual strength.

- High Pre-Tension: The ratchet allows the operator to gradually apply and accumulate tension. Ratchet tensioners manufactured by SMK are designed to ensure the webbing tightly conforms to the cargo, pressing the load firmly against the transport surface. This is crucial for securing heavy equipment, machinery, or high-value loads, effectively preventing shifting during bumpy transit.

- Working Load Limit (WLL): Ratchet-style E Track Straps generally have a higher WLL. At Zhangjiagang SMK MFG. Co., Ltd., our ratchet metal components undergo stringent ultimate load testing in our in-house testing labs, ensuring their safety and reliability meet or exceed international standards (such as GS certification requirements).

- Durability and Security: SMK uses high-strength steel for the ratchet body, applied with premium anti-corrosion treatments (such as galvanizing or high-quality powder coating). We place special emphasis on the ratchet's locking mechanism, ensuring that once tightened, it reliably maintains tension, preventing accidental loosening during transport.

2. Typical Application Scenarios:

- Transport of heavy machinery and equipment.

- Long-haul, long-distance transport of large or high-density cargo.

- Heavy loads in refrigerated trucks or enclosed trailers requiring high pre-tension to counteract inertia forces.

II. Cam Buckle Tensioner: The Ideal Choice for Light Loads, Speed, and Ease of Use

The Cam Buckle tensioner, also known as a clip-style buckle, secures the webbing using a simple spring-loaded cam locking mechanism.

1. Core Mechanism and Technical Advantages:

The Cam Buckle maintains tension through the friction between the webbing and the cam. The tension force primarily comes from the operator's manual pull.

- Low Risk of Over-Tensioning: The pulling force of the cam buckle is limited, meaning it is extremely difficult to apply excessive tension to the cargo. This is a critical advantage for fragile, sensitive, or easily deformed loads (such as cardboard packaging, delicate wood products, or plastics).

- Operation Speed and Convenience: Cam Buckle operation is simple and fast, requiring only threading the webbing through the cam and pulling it tight. Release is quick via a push button. This significantly enhances the efficiency of our products in high-frequency loading/unloading or light-duty logistics.

- Economy and Weight: Cam Buckle tensioners are generally lighter and less costly to produce than ratchet types, making them an ideal choice for clients prioritizing cost-effectiveness and operational simplicity.

2. Typical Application Scenarios:

- Securing large-volume but light-weight goods like furniture, appliances, or cartons.

- Quick tying of outdoor sporting goods, 4x4 accessories, or luggage (perfectly aligning with our product range).

- Transporting sensitive cargo that must avoid excessive compression.

III. SMK’s Professional Value and OEM/ODM Advantages

As a global supplier with 8,000 sqm of production space, certified with ISO 9001 and audited by C-TPAT, Zhangjiagang SMK MFG. Co., Ltd. not only offers standard ratchet and cam buckle E Track Straps but also provides flexible OEM/ODM services.

We can customize the ratchet handle length or gear ratio to control pre-tension, or tailor the cam buckle material and size to meet specific WLL and environmental demands. Whether clients require the powerful ratchet leverage for heavy-duty securement or the gentle locking of a cam buckle to protect fragile items, SMK provides high-quality, high-efficiency cargo control solutions manufactured under our strict full-process quality control. Choosing SMK or XSTRAP means choosing the highest quality standards forged by two decades of professional dedication to the global market.

What Unique Advantages Do E Track Straps Have Compared to Traditional S-Hook or J-Hook Tie-Down Straps

In modern logistics and cargo securement, safety and efficiency are the two major core indicators of successful transportation. While traditional S-Hook or J-Hook tie-down straps still have their applications, facing the demands of high-standard, heavy-duty, and complex cargo securement, E Track Straps (E-Track Rail Straps) undoubtedly represent a professional upgrade in technology and safety.

As a specialized manufacturer deeply involved in cargo control products since 2002, Zhangjiagang SMK MFG. Co., Ltd. possesses over twenty years of industry experience and a robust international supply network. Based on a deep understanding of global logistics challenges, our private brand XSTRAP series of E Track Straps fully embodies their distinct advantages over traditional hook-style tie-downs in design and manufacturing.

The following sections will detail the unique value of E Track Straps across four professional dimensions—securement principle, safety, flexibility, and durability—helping our B2B clients recognize the necessity of this product upgrade.

I. Securement Principle Advantage: Multi-Point Fixing and Uniform Load Distribution

1. Limitations of Traditional Hook-Style Straps:

S-Hooks or J-Hooks must rely on limited, specific anchor points (such as trailer side rails, anchor rings, or holes). This often results in the strap applying pressure at only a few isolated points, leading to load concentration. During transit, this can cause excessive stress on anchor points, damage to cargo edges, or the risk of the hook disengaging during bumps.

2. The Revolutionary Securement of E Track Straps:

E Track Straps work in conjunction with the E-Track Rail System installed inside the cargo van or trailer.

- Unlimited Fixing Positions: The E-track rail offers countless connection points along its length. The E-fittings on SMK-manufactured E Track Straps can quickly lock into any slot of the rail, providing extremely high securement density and flexibility.

- Uniform Load Distribution: This capability for multi-point, dense securement allows the pressure and pre-tension on the cargo to be distributed more evenly. This not only better protects the cargo itself (especially sensitive or fragile goods) but also effectively reduces local stress on the vehicle's structure and anchor points.

II. Safety Advantage: Locking Mechanism and Anti-Disengagement Design

1. Potential Risks of Traditional Hooks:

S-Hooks or J-Hooks rely on gravity or simple positioning to maintain connection. Under severe lateral or vertical vibration, if pre-tension slackens, the hook may accidentally pop out of the anchor point, potentially leading to a major safety incident.

2. E Track Straps' Active Locking Mechanism:

The E-fittings on SMK's E Track Straps utilize an advanced spring-loaded locking mechanism.

- Active Locking: Once the fitting is inserted into the track, a spring-driven locking tab engages the slot. This connection is actively locked, not passively hung. Even if the strap tension decreases, the fitting will not easily pull out.

- C-TPAT Compliance: As an enterprise that has passed the C-TPAT anti-terrorism inspection, we are fully aware of the extreme importance of cargo securement. The secure locking provided by E Track Straps ensures the unwavering stability of high-risk and high-value cargo throughout the entire transportation process.

III. Flexibility and Versatility Advantage: System Expansion Potential

1. Singular Use of Traditional Hooks:

Traditional tie-down straps primarily function to apply pressure. They cannot be directly used for decking or vertical support.

2. Systemic Application of E Track Straps:

The E-track is a complete cargo control system. SMK can provide comprehensive solutions that greatly expand the functionality of E Track Straps:

- Vertical/Horizontal Decking: E Track Straps can be used in conjunction with Decking Beams to create multi-level loading spaces within the trailer, effectively utilizing vertical capacity and maximizing logistics efficiency.

- Auxiliary Attachments: The system supports accessories like O-rings and Wood Beam Sockets, allowing operators to create customized securement plans based on cargo shape and size. This is particularly relevant for securing our 4x4 accessories or complex industrial equipment.

IV. Durability and Quality Assurance

Zhangjiagang SMK MFG. Co., Ltd. operates with 8,000 sqm of production space and is equipped with advanced automated production lines and in-house testing labs.

- Metal Component Lifespan: Compared to S-Hooks and J-Hooks, which can suffer wear from localized friction or bending, the contact surface design of SMK-produced E-fittings with the rail is more scientific. Coupled with our professional anti-corrosion treatment (such as high-quality galvanizing), this ensures the metal components' durability under long-term, high-intensity use.

- Full-Process Quality Control: All our E Track Straps products comply with the ISO 9001 Quality Management System and hold multiple GS Certifications. This full-process quality control ensures E Track Straps provide more reliable and lasting security assurance in terms of both WLL and BS than traditional hook-style tie-downs.

Choosing SMK’s E Track Straps means choosing an upgrade from conventional "fixing" to professional "control"; it means choosing higher safety, greater flexibility, and more enduring durability.

What is the Correct Storage and Maintenance Method for E Track Straps

Cargo tie-down straps are more than just tools—they are vital assets ensuring logistics safety, regulatory compliance, and the protection of high-value goods. The performance and lifespan of E Track Straps, as components of a professional cargo control system, depend directly on proper storage and maintenance.

Since its founding in 2002, Zhangjiagang SMK MFG. Co., Ltd. has been committed to providing the highest quality cargo securing products globally. We understand that even the highest standard strap will have its lifespan severely reduced without proper upkeep. Our in-house brand XSTRAP products, from high-strength webbing to precision ratchets, are manufactured under the ISO 9001 Quality Management System, but correct user maintenance is key to prolonging their superior performance.

Here is a professional guide to the storage and maintenance of E Track Straps, designed to help clients maximize the lifespan of their straps and guarantee safety during every transport.

I. Principles of Daily Storage for E Track Straps

Improper storage is a primary cause of premature strap degradation. The correct storage environment must adhere to the following principles:

1. Protection from Environmental Damage: Dry, Dark, Chemical-Free

- Control Humidity and Moisture: Although the metal components of E Track Straps (E-fittings, ratchets) receive professional galvanized or powder-coated anti-corrosion treatment, prolonged storage in humid environments can accelerate oxidation and rust. If webbing is rolled up while wet, it can develop mold, damaging the fiber structure. Therefore, all straps must be completely dried before storage and kept in a dry, well-ventilated area.

- Isolate from Chemicals: Polyester webbing is highly susceptible to damage from strong acids, alkalis, and certain solvents. Even brief contact can severely reduce its strength. The storage area should be kept away from corrosive chemicals like battery fluid, fuels, and cleaning agents. SMK advises clients to thoroughly inspect and safely clean straps after transporting chemical goods.

- Prevent UV Exposure: Although our XSTRAP webbing offers good UV resistance, prolonged exposure to direct sunlight accelerates the aging and degradation of the polyester fibers, reducing the Working Load Limit (WLL). Straps should be stored indoors in a cool, dark place or covered.

2. Standardized Organization: Avoid Tangling and Damage

- Neat Coiling: After use, the strap should be straightened and neatly coiled. Tangling not only wastes time during the next use but, more critically, haphazard stacking can lead to the webbing being accidentally cut or crushed by sharp objects (such as tools or metal edges), causing localized damage.

- Use Dedicated Storage: It is recommended to use specialized storage bags, hooks, or racks to prevent straps from lying directly on the floor where they might be run over by vehicles or damaged by falling heavy objects. This is particularly important for the precision gears of the ratchet mechanism.

II. Maintenance and Cleaning Methods for E Track Straps

Regular cleaning and maintenance are key to ensuring the performance of both the tensioning devices (ratchets/cam buckles) and the webbing.

1. Lubrication Maintenance for Ratchets and Metal Components

- Clean the Mechanism: In heavy-duty and dusty environments, the interior of the ratchet mechanism can accumulate dirt, sand, or grease, affecting the engagement of the gears and pawls. Use compressed air or a brush to remove debris.

- Regular Lubrication: Apply a moderate amount of lubricant to the ratchet's axles and moving parts. Use a light machine oil to ensure the ratchet operates smoothly and the handle springs back effectively. This not only extends the mechanism's lifespan but also enables the operator to apply pre-tension more efficiently, enhancing cargo securement safety.

2. Webbing Cleaning Procedures

- Gentle Washing: If the webbing is soiled with dirt or salt, use mild soap and a soft brush for cleaning. Strong bleach or corrosive cleaners are strictly prohibited.

- Thorough Drying: After cleaning, the webbing must be completely air-dried in a cool, ventilated area before being coiled for storage.

III. SMK’s Professional Guarantee: From Manufacturing to Maintenance Support

As a professional manufacturer with three factories and 8,000 sqm of production space, Zhangjiagang SMK MFG. Co., Ltd.’s advantage lies not only in the superior quality of our products (such as GS and multiple patent certifications) but also in our commitment to the entire product lifecycle.

The extreme testing conducted in our in-house testing labs ensures the design of XSTRAP products offers high durability. By professionalizing maintenance knowledge, we help clients fully leverage the potential of our products' high-abrasion resistance polyester fiber and anti-corrosion treated metal components. Proper storage and maintenance are the best ways for clients to protect their investment and trust in our products.