Since its establishment in 2002,

Zhangjiagang SMK MFG. Co., Ltd.

has specialized in cargo securing and control products, with over 20 years of experience in R&D and global export. The company is China 4 Inch Ratchet Straps Manufacturers and Custom 4 Inch Ratchet Straps Suppliers, and operates three factories and a large-scale warehouse center, forming an efficient international supply network.

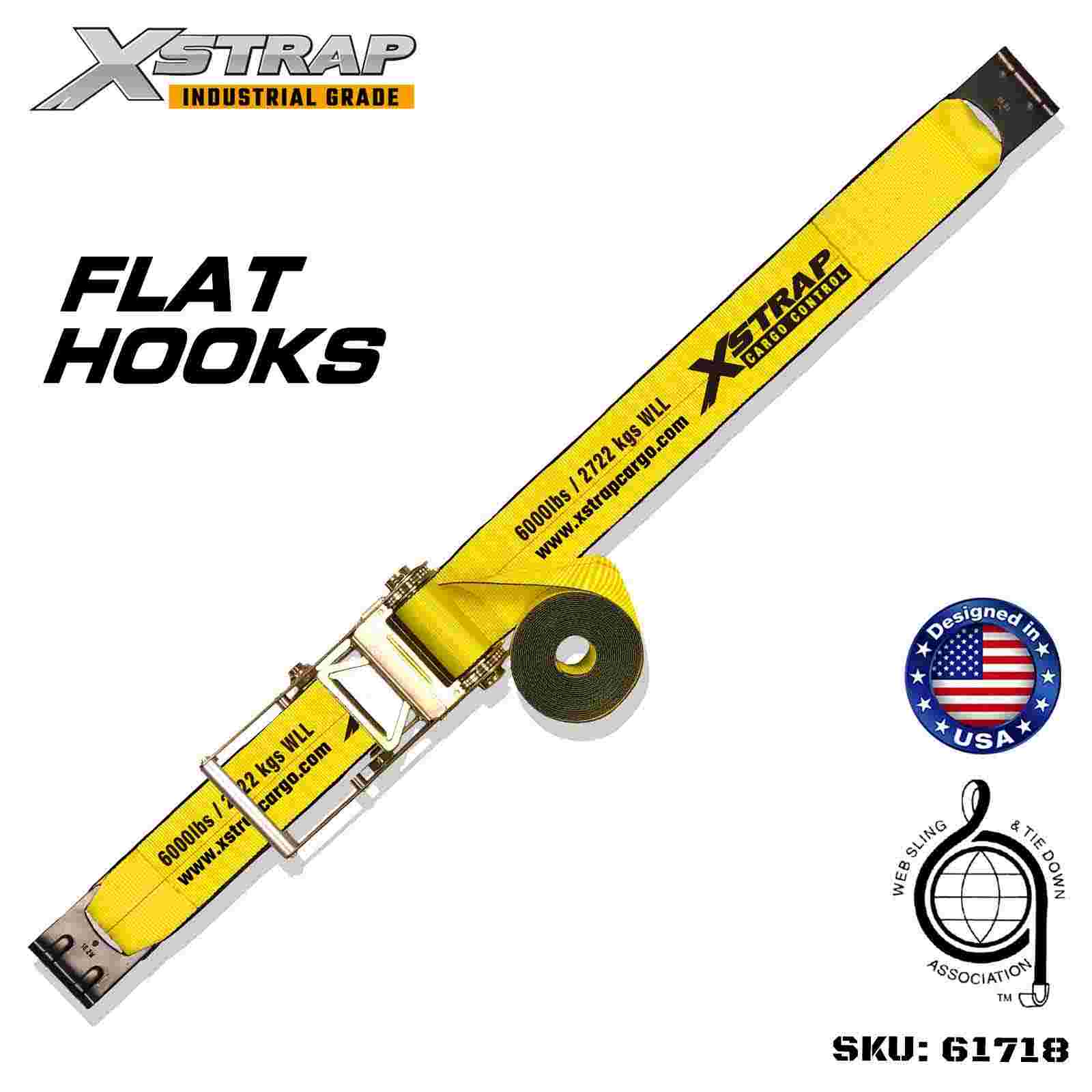

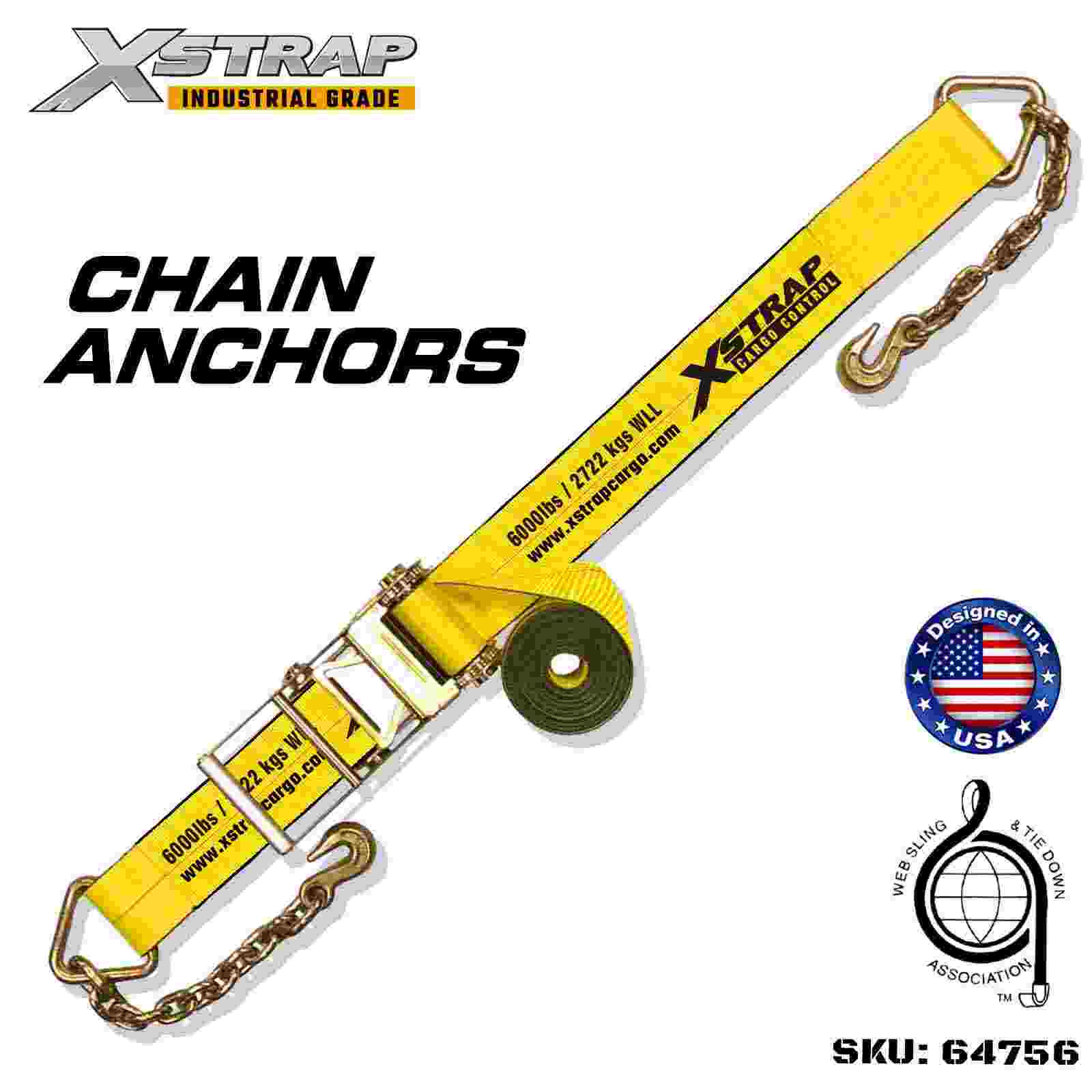

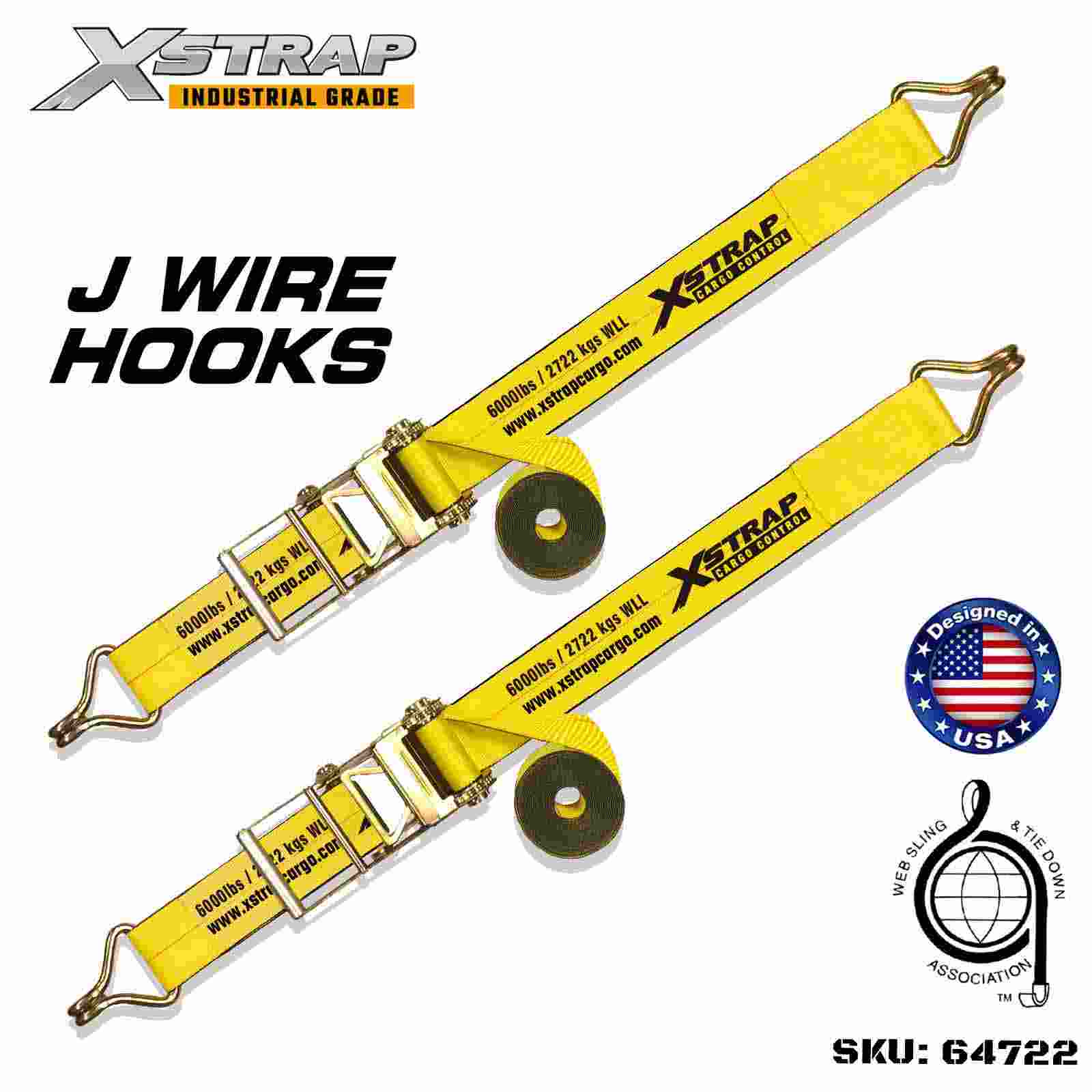

SMK's product range includes tie-down straps, bungee cords, tow straps, lifting slings, hoists, and 4x4 accessories, widely used in transportation, logistics, outdoor, and industrial sectors. Its in-house brand XSTRAP enjoys strong recognition in global markets, alongside flexible OEM/ODM services for customized needs.

With over 8,000 sqm of production space, SMK is equipped with advanced automated lines and in-house testing labs, ensuring full-process quality control from raw material to finished goods. The company is ISO 9001 certified, SMETA audited, and has passed C-TPAT anti-terrorism inspections and multiple GS and patent certifications.

Looking ahead, SMK will continue to upgrade its cargo control systems, stay close to customer needs, and provide high-quality, efficient products and services worldwide.

Product

-

New Products

- Flatbed Solutions

- Interior Van Solutions

- Utility Tie down and Bungee Cord

- Auto Transport and Towing Solutions

- Lifting Solutions

- Tie Down Hardware

-

TUV&GS Certificated Tie Down and Bungee Cord

-

Towing & Rigging

-

4×4 Off-Road & Trailers

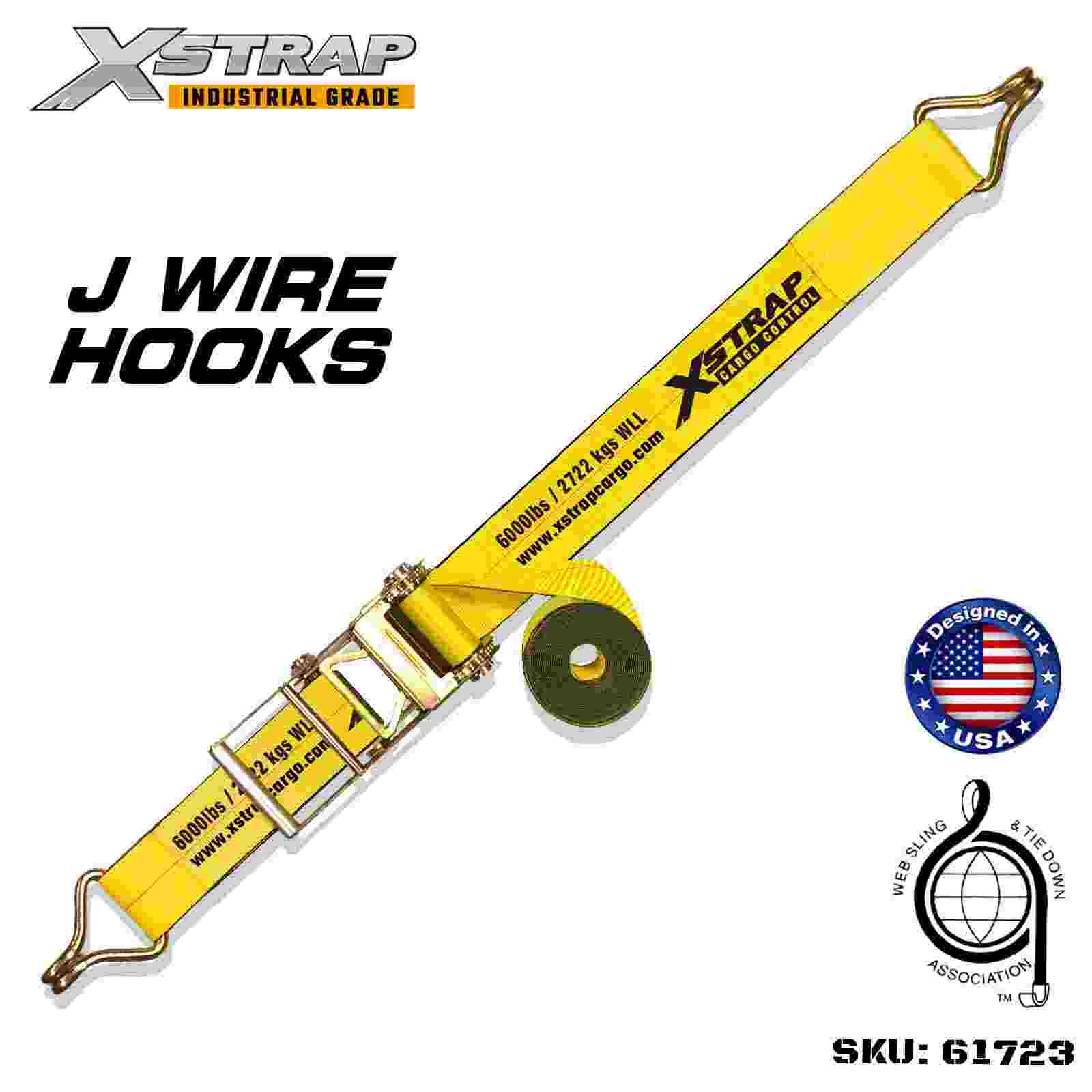

Wholesale and manufactures of 4 Inch Ratchet Straps industrial grade

-

Understanding the Role of Tow Dolly Basket Straps in Vehicle Transport In the field of vehicle transport, Tow Dolly Basket Straps are recognized as one of the safest and most stable securing tools ava...

READ MORE -

1. Understanding the Role of Chain Binders in Load Securement In the world of heavy transportation, Chain Binders are essential tools for ensuring cargo stability. They utilize either a lever principl...

READ MORE -

Understanding the Role of Car Tie Down Straps in Vehicle Transport Safety is the primary consideration when transporting a vehicle. Although standard cargo straps may look similar to Car Tie Down Stra...

READ MORE -

In the field of cargo transportation, securing loads is crucial to ensure the safety of both the cargo and the vehicle. Over the years, ratchet straps have been widely used to secure loads. However, w...

READ MORE

How is the Working Load Limit (WLL) of 4 Inch Ratchet Straps Calculated and Determined?

What is the Essential Relationship between WLL and Breaking Strength (BS)?

To understand WLL, one must first grasp a more fundamental concept: the Breaking Strength (BS), sometimes referred to as the Minimum Breaking Strength (MBS).

Breaking Strength (BS) is the maximum static tensile force that a new, intact 4 inch ratchet strap system (including webbing, ratchet, and end fittings) can withstand before failure or breakage under controlled laboratory conditions.

The Working Load Limit (WLL) is the safe carrying capacity limit calculated based on the breaking strength.

In the international cargo securing industry, a common Safety Factor of 3:1 is applied to polyester (Polyester) webbing products. This means the WLL is only one-third of the BS. For example, a 4 inch ratchet strap with a BS of 15,000 lbs (approx. 6,800 kg) should have its WLL determined as 5,000 lbs (approx. 2,268 kg).

SMK's Professional Commitment:

As an enterprise with over 20 years of experience, ISO 9001 certification, GS certification, and multiple patents, Zhangjiagang SMK MFG. Co., Ltd. strictly adheres to this 3:1 industry standard. The WLL marked on our in-house brand XSTRAP series 4 inch straps is repeatedly verified through our advanced in-house testing labs, ensuring every product offers a reliable safety margin and never exceeds the stated rating.

What are the Three Key Elements for Determining WLL?

The final WLL of a 4 inch ratchet strap must consider all components of the system, as the “Weakest Link Principle” dictates the overall safety.

- 1. Strength of the Webbing

The polyester webbing is the main load-bearing element. Its strength depends on: raw material quality (high-tenacity, low-stretch polyester fiber), weave density and process (our automated production lines across over 8,000 sqm ensure uniform, tight weaving), and anti-aging treatment (special UV and weather resistance to minimize environmental degradation).

- 2. Structural Integrity of the Ratchet Mechanism

The ratchet is critical for applying and maintaining tension. Zhangjiagang SMK MFG. Co., Ltd. ensures the use of high-strength steel, professional heat treatment, and high manufacturing precision to prevent jamming or structural failure. Reliable anti-corrosion treatment (galvanization or coating) maintains long-term strength and smooth operation in harsh environments.

- 3. Load Capacity of End Fittings

Whether flat hooks, snap hooks, or D-rings, the connection and inherent strength of the fitting are crucial. The WLL must be calculated based on the BS of the single weakest component in the entire strap assembly. With rich OEM/ODM experience, we ensure all hardware strength matches the 4 inch webbing, providing reliable products compliant with GS and multiple patent certifications.

How Does Strict Adherence to Industry Standards Ensure Product Quality?

The final WLL labeling must comply with international transport and safety standards, such as Europe's EN 12195-2.

Zhangjiagang SMK MFG. Co., Ltd. has passed C-TPAT anti-terrorism inspections and SMETA audits, and our products hold multiple GS certifications. This signifies that every stage of our 4 inch ratchet strap production, from design to exit, fully complies with stringent international cargo securing standards, providing global customers with a strong guarantee of quality and compliance.

What are the Advantages and Disadvantages of the Main Webbing Materials for 4 Inch Ratchet Straps?

What are the Advantages and Disadvantages of Polyester?

Polyester is the most widely used and recommended material for 4 inch ratchet straps in global cargo control systems.

Advantages:

- Extremely Low Elongation: Typically below 10% (often 3% to 5%) at WLL, which means it maintains maximum Pre-tension Force for stable and secure heavy cargo, the highest safety assurance.

- Excellent Weather and UV Resistance: Slows down fiber degradation and extends product lifespan in outdoor environments.

- Acid Resistance: Good resistance to diluted acids.

- Low Absorption: Minimal effect on strength and flexibility even in wet conditions.

Disadvantages: Poor resistance to strong alkaline substances upon long-term exposure; lacks the elastic cushioning of Nylon.

What are the Advantages and Disadvantages of Nylon?

Nylon's high elongation makes it excellent for Tow Straps (another key product line of Zhangjiagang SMK MFG. Co., Ltd.) but is less ideal for securing straps.

Advantages:

- High Elongation and Impact Cushioning: Can stretch 15% to 30%, absorbing huge momentary impact forces.

- Excellent Alkaline Resistance: Better resistance to alkaline substances than polyester.

- High Abrasion Resistance: Generally superior to polyester fibers.

Disadvantages: Unsuitable for precision securing (prone to loosening due to high stretch); high water absorption (strength may decrease by 10% to 15% when wet); slightly weaker UV resistance than polyester.

Where are Zhangjiagang SMK MFG. Co., Ltd.'s Professional Choice and Quality Assurance Reflected?

Based on our deep understanding of material properties, Zhangjiagang SMK MFG. Co., Ltd. primarily uses high-tenacity polyester fiber for its 4 inch ratchet straps. Leveraging strong R&D and OEM/ODM services, we offer:

- Full-Process Quality Control: Our in-house testing labs ensure every batch of polyester webbing meets the predetermined Breaking Strength (BS) standards.

- Compliance Advantage: Our factory is SMETA audited, and products hold multiple GS certifications, confirming compliance with the strictest international safety standards.

- Customization and Innovation: We can flexibly adjust material formulas or use custom coatings based on specific customer needs (e.g., applications in highly alkaline environments).

Compared to 2 Inch or 3 Inch Ratchet Straps, What are the Irreplaceable Advantages of 4 Inch Ratchet Straps in Specific Industries or Heavy Cargo Transport Scenarios?

What is the Core Advantage of 4 Inch Ratchet Straps?

The core value of the 4 inch ratchet strap lies in its overwhelming Working Load Limit (WLL).

- Exponential Increase in WLL:

While standard 2 inch straps are often below 3,333 lbs WLL, high-quality 4 inch ratchet straps can often easily reach 5,400 lbs to 6,670 lbs (approx. 2.45 to 3 metric tons) or higher. This allows for compliance with international regulations (like FMCSA or EN 12195-2) using fewer straps, ensuring efficient and safe securing.

- Superior Tension Distribution:

The 4 inch (approx. 10 cm) width distributes tension over a larger cargo surface area. This effectively reduces localized pressure concentration, minimizes the risk of webbing abrasion against sharp edges, and provides better protection for sensitive cargo.

What are the Irreplaceable Application Scenarios for 4 Inch Straps?

In these specific industries, 4 inch ratchet straps are the indispensable choice for safety and compliance:

- Construction and Heavy Machinery Transport: Securing single, heavy, and high-center-of-gravity items (e.g., bulldozers, excavators). The 4 inch strap provides sufficient tension and grip to counteract lateral and longitudinal movement.

- Oil, Gas, and Energy Sectors: Bundling large pipelines, industrial tanks, and generators, often weighing tens of tons. The 4 inch width and strength allow for more stable securing across large cylindrical structures.

- Steel, Lumber, and Raw Material Transport: Securing high-density, sharp-edged loads (e.g., bundles of steel beams, coils, or logs). The larger surface area, when used with corner protectors, maximizes resistance to cutting and improves system durability.

- Specialized and Military Cargo Transport: Standard equipment for securing heavy flatbed trailer loads (e.g., modular housing, customized containers). The heavy-duty cast ratchet mechanism provides a greater tension handle leverage, enabling operators to apply higher pretension for zero movement over rough terrain.

With ISO 9001 certification and high-standard manufacturing processes, Zhangjiagang SMK MFG. Co., Ltd. ensures professionally reinforced webbing edges, maintaining high durability against sharp edges.

How to Correctly Release and Unlock 4 Inch Ratchet Straps?

What are the Pre-Release Preparation and Safety Assessments?

Correctly releasing a 4 inch ratchet strap is crucial for preventing the “Snapback Effect” and accidental cargo shifting, ensuring operator safety.

- Assess Cargo Stability: Confirm the cargo is independently stable. Use temporary external supports (e.g., blocks, outriggers) or slight pre-lifting with lifting slings (another specialty product of Zhangjiagang SMK MFG. Co., Ltd.) if necessary.

- Choose Release Direction and Stance: Operators must always stand outside the safety zone of the cargo and the potential path of the snapping handle or webbing.

- Wear Personal Protective Equipment (PPE): Safety glasses and protective gloves are mandatory.

What are the Professional Unlocking Steps for 4 Inch Ratchet Straps?

Releasing a high-tension 4 inch ratchet strap must be precise and controlled, aiming for a Controlled Release:

- Step 1: Locate and Operate the Release Lever

Fully grip the handle, use the thumb or finger to lift or press down the release lever (or pawl), simultaneously wiggling the handle slightly to confirm the lever has fully disengaged the ratchet gear.

- Step 2: Fully Open and Lock the Handle

While keeping the release lever held down, fully open the ratchet handle to the 180-degree flat position (or unlock/full-open mode). The pawl should be locked up, disengaged from the gear. The handle and ratchet frame should form a straight line.

SMK Design Advantage: Our XSTRAP ratchet mechanisms, verified through precise OEM/ODM design, ensure the mandrel rotates freely in the full-open position for quick strap withdrawal, balancing heavy-duty requirements with user-friendliness.

- Step 3: Slowly Release Tension (Controlled Slack)

With the handle flat open, gently pull the webbing or carefully push the cargo to allow the mandrel to begin rotating backward. Safety Tip: For heavy cargo, the initial tension release must be extremely slow to prevent rapid webbing withdrawal or cargo kickback.

- Step 4: Remove Webbing and Secure Closure

Once tension is fully released, pull the webbing end out of the mandrel. For stowage, close the ratchet handle and relock it into the “Store/Ready Mode”, protecting the gear from contamination and extending product life.

What are the Special Issues in Heavy Load Release and SMK's Quality Assurance?

4 inch ratchet straps can encounter "jamming" or "over-tensioning" issues in harsh environments:

- Release Difficulty Due to Over-Tensioning:

If the pretension is too high, the release lever might be too stressed to unlock. Solution: First perform a few small re-tensioning strokes (crank the handle 1-2 times) to momentarily relieve extreme pressure on the mechanism, then attempt to press the release lever to the flat-open position.

- Jamming Due to Corrosion and Debris:

Contamination or rust can affect unlocking. SMK Advantage: Utilizing advanced automated production lines and stringent metal treatment processes, Zhangjiagang SMK MFG. Co., Ltd. ensures all ratchet components have excellent corrosion resistance. Our GS and multiple patent-certified products are designed to withstand harsh environments, minimizing the safety risk of mechanism jamming.

With over two decades of professional experience, Zhangjiagang SMK MFG. Co., Ltd. guarantees that every 4 inch ratchet strap system we manufacture provides a safe, reliable, and efficient securing and releasing experience. Correct operation combined with our high-standard quality products is the ultimate guarantee in your cargo transport safety chain.