Since its establishment in 2002,

Zhangjiagang SMK MFG. Co., Ltd.

has specialized in cargo securing and control products, with over 20 years of experience in R&D and global export. The company is China 3 Inch Ratchet Straps Manufacturers and Custom 3 Inch Ratchet Straps Suppliers, and operates three factories and a large-scale warehouse center, forming an efficient international supply network.

SMK's product range includes tie-down straps, bungee cords, tow straps, lifting slings, hoists, and 4x4 accessories, widely used in transportation, logistics, outdoor, and industrial sectors. Its in-house brand XSTRAP enjoys strong recognition in global markets, alongside flexible OEM/ODM services for customized needs.

With over 8,000 sqm of production space, SMK is equipped with advanced automated lines and in-house testing labs, ensuring full-process quality control from raw material to finished goods. The company is ISO 9001 certified, SMETA audited, and has passed C-TPAT anti-terrorism inspections and multiple GS and patent certifications.

Looking ahead, SMK will continue to upgrade its cargo control systems, stay close to customer needs, and provide high-quality, efficient products and services worldwide.

Product

-

New Products

- Flatbed Solutions

- Interior Van Solutions

- Utility Tie down and Bungee Cord

- Auto Transport and Towing Solutions

- Lifting Solutions

- Tie Down Hardware

-

TUV&GS Certificated Tie Down and Bungee Cord

-

Towing & Rigging

-

4×4 Off-Road & Trailers

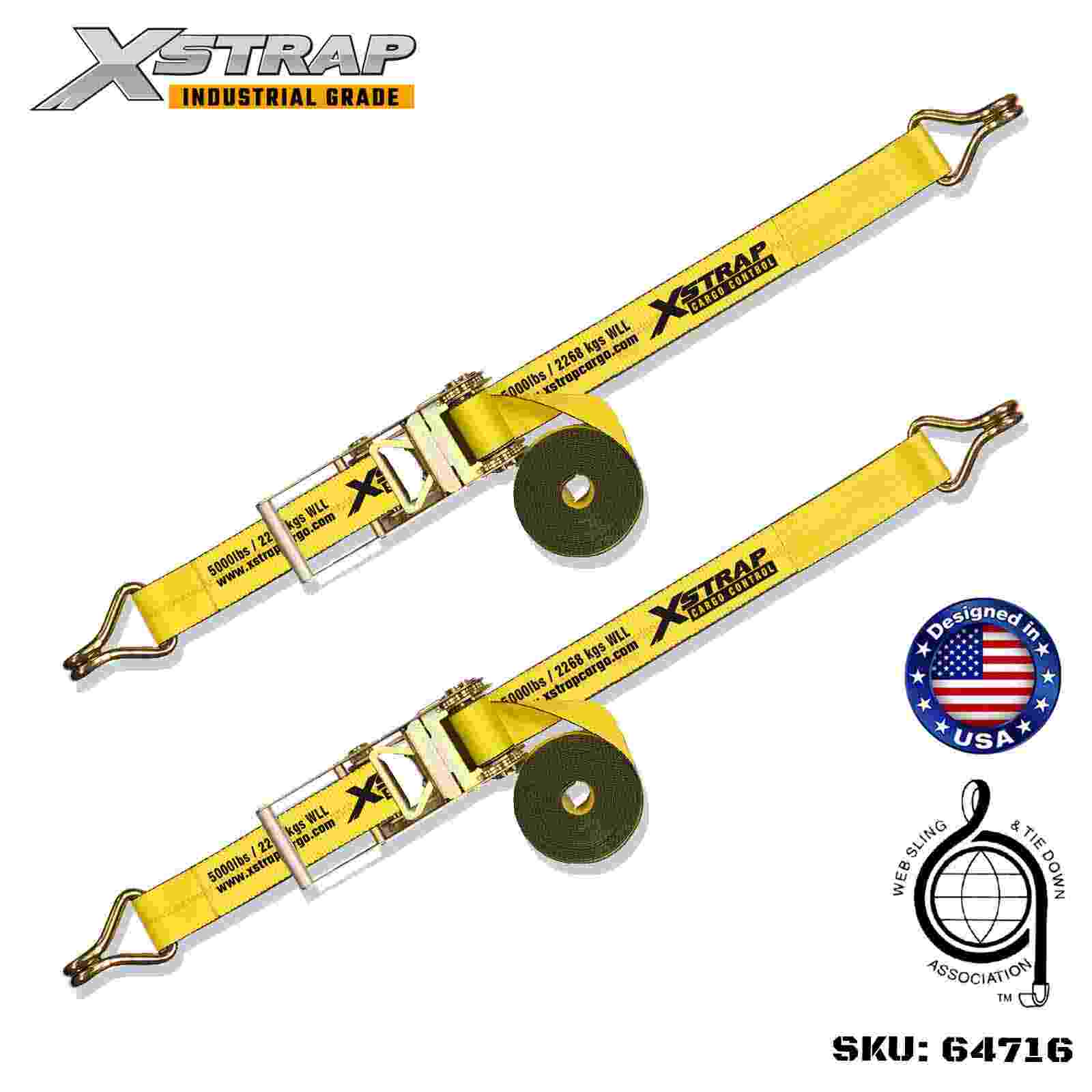

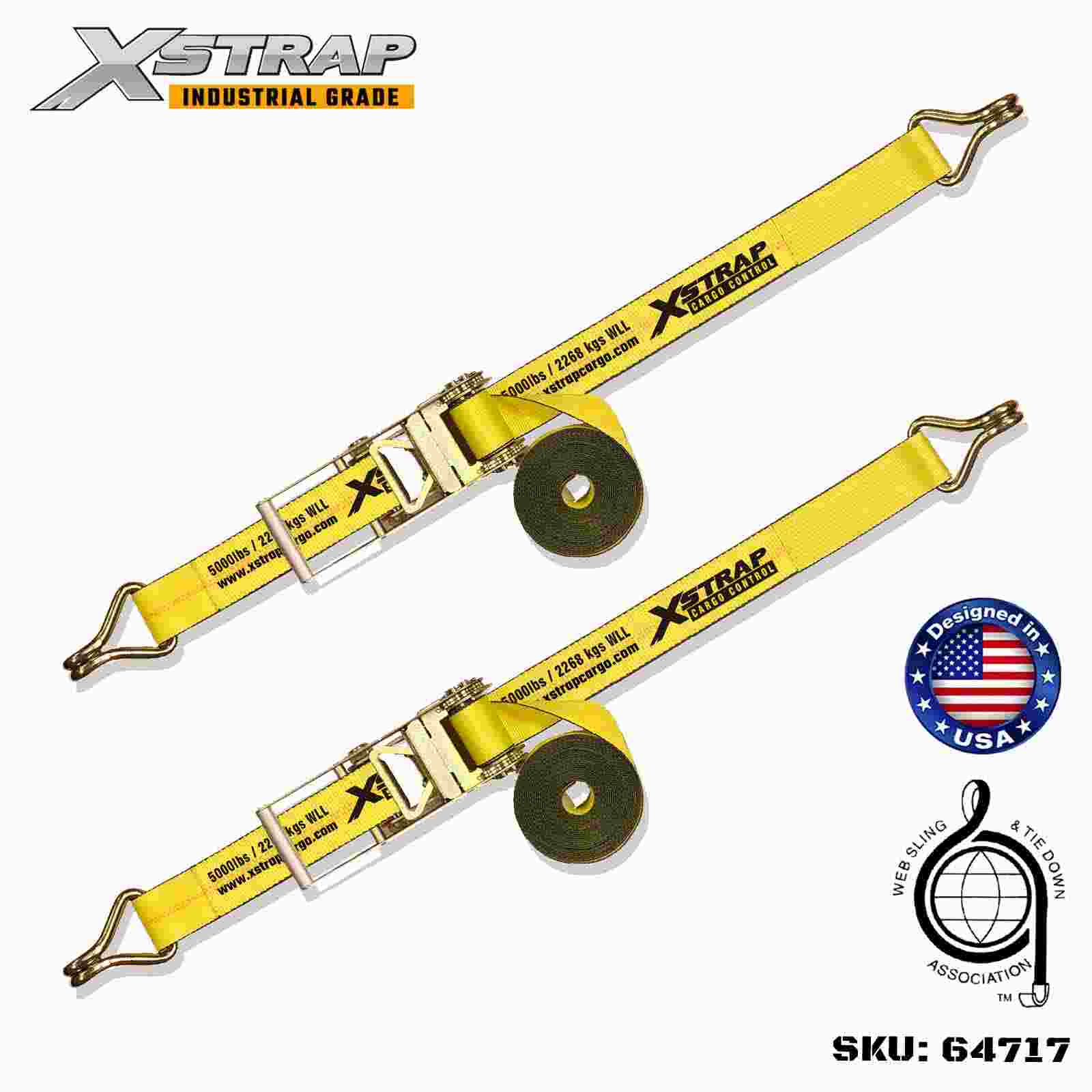

Wholesale and manufactures of 3 Inch Ratchet Straps industrial grade

-

Understanding the Role of Tow Dolly Basket Straps in Vehicle Transport In the field of vehicle transport, Tow Dolly Basket Straps are recognized as one of the safest and most stable securing tools ava...

READ MORE -

1. Understanding the Role of Chain Binders in Load Securement In the world of heavy transportation, Chain Binders are essential tools for ensuring cargo stability. They utilize either a lever principl...

READ MORE -

Understanding the Role of Car Tie Down Straps in Vehicle Transport Safety is the primary consideration when transporting a vehicle. Although standard cargo straps may look similar to Car Tie Down Stra...

READ MORE -

In the field of cargo transportation, securing loads is crucial to ensure the safety of both the cargo and the vehicle. Over the years, ratchet straps have been widely used to secure loads. However, w...

READ MORE

What Are the Common End Fittings for 3 Inch Ratchet Straps?

In the field of heavy cargo securing, 3 Inch Ratchet Straps are the professional tool ensuring the safe transit of large equipment, construction materials, and oversized loads. However, a strap's strength and reliability do not just rely on its 16,500 lbs (or higher) Breaking Strength (MBS) polyester webbing and powerful ratchet, but crucially on its End Fittings—the "handshake" between the strap and the anchor point. The choice of end fitting directly determines lashing efficiency, suitability for anchor points, and the overall system's Working Load Limit (WLL).

As a specialized manufacturer focused on cargo securing and control products since 2002, Zhangjiagang SMK MFG. Co., Ltd. leverages over 20 years of R&D and global export experience, understanding the rigorous demands for fittings in various transport scenarios. Operating three factories and an efficient international supply network, we provide professional products globally. Our in-house brand XSTRAP series of 3-inch ratchet straps offers a variety of professional end fittings, verified by our in-house testing labs, to meet complex global logistics needs.

Here are the most common end fittings for 3-inch ratchet straps in heavy haulage and their professional applications:

1. Flat Hook

Professional Description: The flat hook is the most common and versatile heavy-duty fitting. It is typically stamped from high-strength steel, featuring a wide, flat contact surface designed to hook into the side rails, gooseneck, or C-Channel openings of a flatbed trailer.

SMK/XSTRAP Advantage: The design focus for the flat hooks produced by Zhangjiagang SMK MFG. Co., Ltd. is the maximization of bearing area and the uniformity of stress distribution. Our flat hooks are zinc or chromate coated for excellent corrosion resistance. During WLL testing, the strength of the flat hook must match that of the 3-inch webbing to ensure it does not become the "weak link" in the entire lashing system. This is a core principle upheld by our ISO 9001 certified and C-TPAT audited quality control system.

Applicable Scenarios: Suitable for flatbed trucks or trailers with standard side rails that provide large opening attachment points. It is the ideal choice for securing large pallets, lumber, and rectangular equipment.

2. Wire Hook / Double J-Hook

Professional Description: The wire hook (or double J-hook) is formed by two bent steel wires, creating a narrower, more gripping J-shaped opening. It is more flexible than the flat hook and can accommodate smaller, deeper anchor points.

SMK/XSTRAP Advantage: For cargo requiring flexible attachment to complex anchor points (such as small anchor holes, chain openings, or narrow access points), the wire hook/double J-hook provided by SMK is the professional solution. Our hook material and heat treatment processes ensure sufficient breaking strength over a smaller contact area. The double J-hook design is particularly stable, effectively preventing accidental disengagement during transport bumps, offering additional security for our customers' heavy machinery, outdoor, and industrial cargo.

Applicable Scenarios: Suitable for compact anchor points on truck chassis, or for use in conjunction with chain attachment points.

3. Chain and Grab Hook End

Professional Description: The chain end typically features a forged grab hook, with the strap stitched to a short length of G70 or G80 alloy steel chain. This configuration combines the flexibility advantage of the webbing with the extreme strength and abrasion resistance of the chain.

SMK/XSTRAP Advantage: This is a premium fitting designed by SMK specifically for the most demanding heavy haulage and engineering applications. Our chain assemblies and grab hooks undergo stringent strength testing and come with full material traceability. With our advanced automated production lines and in-house testing labs, we ensure the stitching connection between the strap and chain meets the highest safety factor. This fitting is an irreplaceable professional solution when cargo must be secured to anchor points designed only for chains (such as designated connection points on excavators or heavy machinery).

Applicable Scenarios: Transporting super heavy equipment, military supplies, or securing to anchor points that require extremely high wear resistance.

4. Delta Ring

Professional Description: The Delta ring is a closed metal ring that offers all-around connection capability. It does not hook directly into an anchor point but serves as an intermediate connector, typically used for passing through cargo or connecting to vehicle anchor points via auxiliary chains.

SMK/XSTRAP Advantage: The primary design advantage of the Delta ring is stress dispersal. As a critical custom option in our OEM/ODM services, Zhangjiagang SMK MFG. Co., Ltd. can provide Delta rings with various sizes and WLLs. Customers can utilize the Delta ring to connect other securement tools based on their unique cargo shape and lashing method, achieving multi-point, balanced lashing. This capability is vital for enhancing our customers' professional capacity in logistics, outdoor, and industrial sectors.

Applicable Scenarios: Used for basket hitches (wrapping around cargo), or as an intermediate piece connecting to other specialized securement points.

Which Major Heavy Transport Scenarios Are Best Suited for 3 Inch Ratchet Straps?

In the field of professional cargo securing, the 3 Inch Ratchet Strap is widely recognized as the gold standard for medium-to-heavy duty transport. Its superior Working Load Limit (WLL), typically reaching 5,400 lbs to 5,500 lbs (or higher), makes it far superior to common 2-inch straps in terms of safety, efficiency, and regulatory compliance, establishing it as a cornerstone of global logistics, construction, and industrial transport.

Since its establishment in 2002, Zhangjiagang SMK MFG. Co., Ltd. has consistently focused on the R&D and global export of cargo securing and control products. We deeply understand the severity of heavy haulage environments. Our product range includes tow straps, lifting slings, hoists, and 4x4 accessories. Through our in-house brand XSTRAP and flexible OEM/ODM services, our 3-inch ratchet straps are widely used across various heavy-duty scenarios globally, ensuring the safe and efficient delivery of millions of tons of cargo.

Here are the core and most critical heavy transport application scenarios for 3-inch ratchet straps, highlighting the professional value and advantages of our products:

1. Securing Heavy Machinery and Equipment on Flatbeds

Scenario Description: Flatbeds are the primary choice for transporting non-standardized, oversized, or overweight items, including heavy construction machinery like excavators, bulldozers, loaders, and crane components. These loads are heavy, have high centers of gravity, and are irregularly shaped, demanding extremely high strength and shock resistance from the tie-down straps.

SMK/XSTRAP Professional Value: The 3-inch strap's wider webbing provides a larger contact area, effectively distributing load pressure and reducing damage to sensitive equipment surfaces. Zhangjiagang SMK MFG. Co., Ltd. uses high-tenacity polyester webbing with an extremely low elongation rate (typically below 7%), ensuring the strap maintains high tension continuously during vehicle acceleration, sudden braking, or bumps, preventing cargo from sliding or tipping on the flatbed. Manufactured on our advanced automated lines within over 8,000 sqm of production space, our 3-inch ratchet mechanisms guarantee reliable and sustained tightening force even in extreme conditions.

2. Logistics for Construction and Steel Structure Materials

Scenario Description: Transporting steel beams, precast concrete segments, large pipes, bundled lumber, or structural steel is routine for construction logistics. These materials often have sharp edges, high density, and long lengths, requiring ultimate abrasion resistance and anti-cutting protection.

SMK/XSTRAP Professional Value: To counter the high abrasion risks posed by construction materials, SMK's 3-inch straps are engineered for superior wear resistance. Furthermore, we strongly advise customers to use Corner Protectors to safeguard the strap, which not only extends product life but also prevents transport delays or accidents caused by strap damage. Our products are ISO 9001 certified, ensuring strict control over raw material quality to maintain the strap's WLL rating even under the immense friction and pressure from heavy loads.

3. Industrial Equipment, Molds, and Containerized Heavy Cargo Securing

Scenario Description: In industrial manufacturing and shipping logistics, high-value precision molds, large machine parts, or heavy cargo secured inside ocean shipping containers require dependable anchoring to withstand long-distance transport, sea swell, or loading/unloading shocks.

SMK/XSTRAP Professional Value: The 3-inch strap is the ideal tool for securing high-value, high-precision industrial equipment. Its high-tension capacity allows for "lashing," firmly pressing the cargo onto the container floor or vehicle deck. Thanks to our supply chain standards, which have passed SMETA audits and C-TPAT anti-terrorism inspections, Zhangjiagang SMK MFG. Co., Ltd. can provide reliable products that meet international compliance requirements for global logistics and multinational manufacturing enterprises. Furthermore, our customized end fittings (such as Delta rings, flat hooks, or chain hooks) flexibly adapt to various anchor point layouts inside containers and vehicle compartments.

4. Specialized Vehicle and 4x4 Accessory Transport and Securing

Scenario Description: While 3-inch straps are primarily used for commercial heavy haulage, they also play a critical role in securing specialized vehicles (like military vehicles, large RVs, race cars) and large 4x4 off-road accessories.

SMK/XSTRAP Professional Value: SMK's product line includes tow straps and 4x4 accessories, giving us an in-depth understanding of specialized vehicle and outdoor transport environments. Our XSTRAP 3-inch straps are designed with UV radiation and moisture exposure in mind. The high-quality polyester webbing features excellent weather and UV resistance, ensuring the WLL remains stable even in long-term exposure to harsh conditions typical of specialized transport. Flexible customization services can even accommodate specific color or stenciling needs for specialty industries.

How to Maximize the Lifespan of 3 Inch Ratchet Straps on Sharp Edges or Rough Cargo?

The 3 Inch Ratchet Strap is a core safety component in heavy haulage, with its high-tenacity polyester webbing offering excellent tensile strength and low elongation for secure cargo fixing. However, in real-world transport, sharp cargo edges, rough surfaces, and continuous vibration friction are the "invisible killers" of webbing lifespan. Once the webbing is damaged, its rated Working Load Limit (WLL) drops sharply, seriously jeopardizing transport safety and regulatory compliance.

As a specialized manufacturer in cargo securing and control since 2002, Zhangjiagang SMK MFG. Co., Ltd. boasts over 20 years of R&D and global export experience. We recognize that providing durable products is only the first step; teaching customers how to professionally protect and use these products fulfills our commitment to "upgrading cargo control systems." Our brand XSTRAP strap series, benefiting from full-process quality control (QC) from raw material to finished goods, is a reliable choice for heavy load protection.

Here are the professional strategies and tools for extending the lifespan of 3-inch ratchet straps and dealing with sharp edges and rough surfaces:

I. Professional Solution for Sharp Edge Protection: Corner Protectors

Corner Protectors are essential accessories in heavy haulage, serving two main professional functions: stress dispersal and preventing abrasion/cutting.

A. Compound Stress Dispersal:

When a strap passes over a sharp corner of the cargo, all tension is concentrated at a tiny contact point, which can easily cut the webbing and apply excessive pressure to the cargo edge. High-quality corner protectors (such as our XSTRAP accessories) disperse the tension applied across the strap's 3-inch width evenly over a wider, smoother curved surface, effectively preserving the webbing's integrity.

B. Material and Application Selection:

Zhangjiagang SMK MFG. Co., Ltd. offers various material options for corner protectors to meet different transport needs:

- High-Density Polyethylene (HDPE) or Engineering Plastic: Suitable for most conventional cargo, providing lightweight yet robust protection.

- Rubber or Elastic Materials: Suitable for irregularly shaped or surface-sensitive cargo, offering cushioning and shock absorption.

- Metal Reinforced Type: Designed for extremely sharp or high-heat steel structures and pipes, providing the strongest anti-cutting and heat resistance.

Professional Tip: Even when using the most durable 3-inch strap, any direct contact between the webbing and a sharp edge can reduce the WLL to an unacceptably dangerous level. Using corner protectors is a necessary operation to comply with industry standards (like FMCSA).

II. Strategies for Dealing with Rough Surfaces and Vibration Abrasion

Continuous friction from rough surfaces, especially under vehicle vibration during long-haul transport, leads to the gradual wear, fraying, and strength loss of the webbing fibers—a common form of "fatigue failure."

A. High-Quality Webbing Abrasion Resistance as the Foundation:

SMK uses advanced automated production lines in its over 8,000 sqm of manufacturing space to strictly control the weaving density and fiber quality of the polyester webbing. Our webbing undergoes special treatment for superior abrasion resistance. Our in-house testing labs regularly conduct abrasion resistance tests on different batches of webbing, ensuring that even when rubbed against rough concrete or stone cargo, the strap's service life is maximized. This is a key reflection of our ISO 9001 and multiple GS certified quality assurance system.

B. Altering the Contact Method Between Strap and Cargo:

For large areas of rough cargo where corner protectors cannot be used (such as large rocks or castings), users should attempt a Basket Hitch lashing, passing the strap through the cargo or encircling an anchor point to minimize sliding friction. Simultaneously, ensure the strap is always taut, as loose straps are more prone to severe friction from vibration.

III. Daily Management and Inspection for Extended Lifespan

Even the most robust 3-inch strap requires professional daily maintenance.

- Re-inspection During Transit: Professional heavy haulage operators should re-inspect and tighten the strap after a short distance (e.g., 5-10 miles or 15 minutes) from the starting point, as cargo may slightly shift after initial stress.

- Regular Cleaning and Storage: Residue like dirt, salt, and chemicals (e.g., oil) on the webbing can accelerate fiber degradation and corrosion. Zhangjiagang SMK MFG. Co., Ltd. recommends storing 3-inch straps in a dry, dark environment (to prevent UV aging) when not in use.

- Retirement Criteria: Any strap showing cuts, chemical burns, severe abrasion leading to fiber breakage, or a missing tag (making WLL information unidentifiable) must be immediately retired. We offer flexible OEM/ODM services to help customers print clear branding and WLL information for easy daily inspection.

How to Professionally Resolve Common Jamming and Slipping Issues with 3 Inch Ratchet Straps?

In the field of heavy cargo securing, the 3 Inch Ratchet Strap stands out for its superior tensioning capability and high Working Load Limit (WLL) of over 5,400 lbs. The core of the strap—the ratchet mechanism—is responsible for generating and maintaining the critical tension that holds heavy cargo firmly to flatbeds or trailers.

However, professional logistics and transport personnel frequently face two technical challenges during use: mechanism Jamming and Slipping after tensioning. Both issues not only affect operational efficiency but can also lead to cargo securement failure, causing serious safety incidents.

Since its founding in 2002, Zhangjiagang SMK MFG. Co., Ltd. has always treated ratchet mechanism reliability as a core focus of product R&D. Our in-house brand XSTRAP and OEM/ODM products are rigorously validated by our internal testing labs. With over 20 years of professional experience, we deeply analyze the precision construction of the ratchet mechanism and provide expert solutions.

I. Diagnosis and Resolution of Ratchet Mechanism “Jamming”

Ratchet jamming usually occurs when attempting to release or tighten, preventing the operator from proceeding. This is often caused by the following three main reasons:

1. Webbing Overload on the Mandrel:

This is the most common cause. If too much webbing is wound onto the ratchet's axle (Mandrel) during tensioning, the axle's effective diameter becomes too large, preventing the ratchet from turning or releasing.

SMK/XSTRAP Solution and Prevention: During initial threading, ensure only a manageable amount of "working" webbing is left for tensioning. Our 3-inch ratchet mechanism design structurally optimizes the clearance between the axle and the casing to minimize entanglement risk. If jamming occurs, try opening the ratchet mechanism to the fully flat "release" position, pulling outwards to relieve pressure on the axle, and then carefully pull the excess webbing out of the mandrel.

2. Mechanism Corrosion and Dirt Accumulation:

In outdoor and industrial environments, dust, dirt, salt, and moisture can enter the ratchet's gear and pawl mechanism, leading to rust and seizing.

SMK/XSTRAP Product Advantage: Ratchet mechanisms manufactured by Zhangjiagang SMK MFG. Co., Ltd. typically feature high-standard zinc or chrome plating to offer superior corrosion resistance. This level of quality is enforced by our rigorous standards, including C-TPAT anti-terrorism inspection and SMETA audit. For mechanisms with dirt accumulation, we recommend using an air gun or stiff brush for cleaning, and periodically applying light lubricant (avoiding heavy grease that can attract dirt).

3. Pawl/Spring Failure:

Damage or deformation to the internal pawl or return spring can prevent the ratchet from unlocking.

Professional Advice: SMK strictly controls the quality of all ratchet mechanism components. Any damage to the pawl or spring indicates the strap is unsafe and must be retired. Our ISO 9001 quality management system ensures every ratchet mechanism leaving our facilities has passed stringent stress testing to minimize the chance of this type of failure.

II. Root Causes and Elimination of Tension “Slipping”

Tension slipping after the strap is secured is the greatest safety hazard in transit, typically related to improper operation and mechanism deterioration:

1. Insufficient Strap Angle and Friction:

In extreme transport conditions, if there is insufficient friction between the cargo and the trailer deck, the strap tension can gradually decay due to minute cargo shifting.

Professional Solution: SMK advises professional users to ensure the strap is secured at the correct angle (ideally close to 45 degrees) to achieve "Friction Tie-Down." Simultaneously, ensure the tension is sufficiently high, which relies on the powerful leverage and locking capacity provided by our high-quality ratchet mechanisms.

2. Worn Pawls or Gears:

Long-term use or overloading can cause wear to the internal gears and pawls of the ratchet mechanism, leading to insecure locking.

SMK/XSTRAP Quality Assurance: In the internal testing labs of Zhangjiagang SMK MFG. Co., Ltd., we subject our 3-inch ratchet mechanisms to cyclical durability tests far exceeding industry standards. High-quality steel and precise stamping ensure perfect gear tooth engagement, effectively preventing slipping. The vertical integration and full-process QC across our three factories guarantee the locking consistency and long-term reliability of our finished products.

3. Webbing Elongation or Elastic Deformation:

Lower-quality webbing may experience irreversible elongation when subjected to heavy load tension, resulting in tension loss.

SMK/XSTRAP Webbing Advantage: Our XSTRAP 3-inch straps use high-density polyester fiber, characterized by low elongation. This means that the length change after initial tensioning is minimal, maximizing the retention of initial tension.