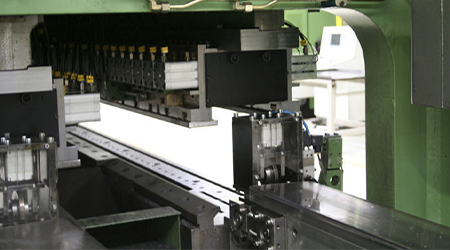

Manufacturing Process

Quality Control

Materials Selection

Our ratchet tie-downs use high-strength, abrasion-resistant polyester webbing.

Metal components such as hooks and buckles are made from corrosion-resistant, high-tensile alloys.

For lifting slings and safety harnesses, we use certified yarns and webbings that meet safety standards to ensure durability and load-bearing capacity.

All materials comply with GS (German Safety) and EC (European Commission) standards to meet international market requirements.

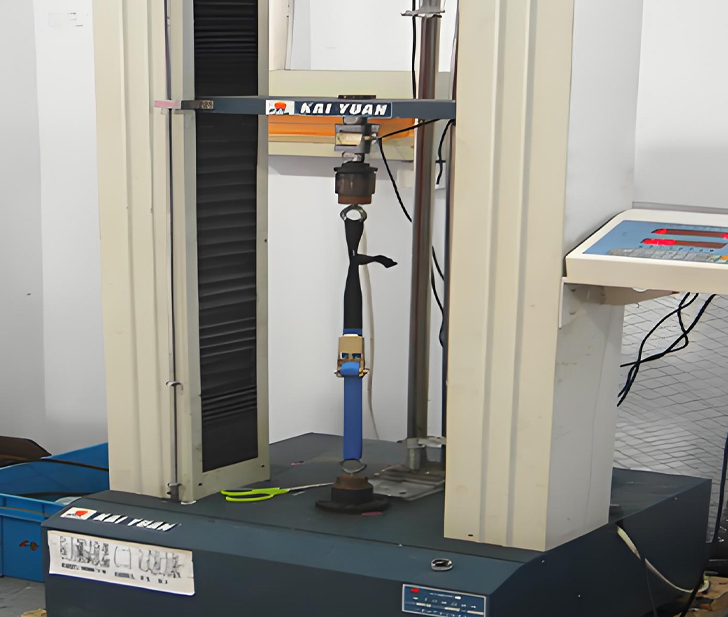

Laboratory

SMK has established a comprehensive in-house quality lab equipped with advanced testing instruments, enabling full-process monitoring from raw material intake to final shipment.

To meet compliance requirements across global markets, we support third-party certifications (e.g. TUV, SGS, BV) and offer custom testing or parameter adjustments upon request—enhancing market access and brand credibility.